Page 299 - Orlicky's Material Requirements Planning

P. 299

278 PART 3 Managing with the MRP System

the manufacturer can build more closely to actual consumption in the supply chain. This

approach was introduced in Chapter 2. The benefit for the manufacturer is that the fore-

casts are more accurate, and production resources are allocated to items that will really

sell without a major reduction in price.

If safety stocks were calculated using the traditional statistical methods, the

required safety stock to provide 95 percent customer service would be 805 units. If this is

applied to the planning from Figure 15-4, the result would be as shown in Figure 15-5.

The combination of the safety stock and fixed order quantity yields an amazing

average inventory of 1,640 units. This is over twice the expected safety stock. When this

is considered on an enterprise-wide level, the assets dedicated to this hidden inventory

could be significant. As an alternative, if visibility existed of the entire inventory in the

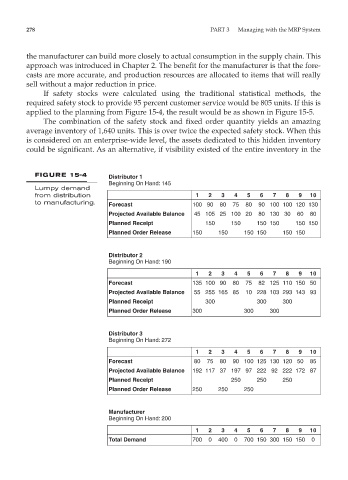

FIGURE 15-4 Distributor 1

Beginning On Hand: 145

Lumpy demand

from distribution 1 2 3 4 5 6 7 8 9 10

to manufacturing. Forecast 100 90 80 75 80 90 100 100 120 130

Projected Available Balance 45 105 25 100 20 80 130 30 60 80

Planned Receipt 150 150 150 150 150 150

Planned Order Release 150 150 150 150 150 150

Distributor 2

Beginning On Hand: 190

1 2 3 4 5 6 7 8 9 10

Forecast 135 100 90 80 75 82 125 110 150 50

Projected Available Balance 55 255 165 85 10 228 103 293 143 93

Planned Receipt 300 300 300

Planned Order Release 300 300 300

Distributor 3

Beginning On Hand: 272

1 2 3 4 5 6 7 8 9 10

Forecast 80 75 80 90 100 125 130 120 50 85

Projected Available Balance 192 117 37 197 97 222 92 222 172 87

Planned Receipt 250 250 250

Planned Order Release 250 250 250

Manufacturer

Beginning On Hand: 200

1 2 3 4 5 6 7 8 9 10

Total Demand 700 0 400 0 700 150 300 150 150 0