Page 296 - Orlicky's Material Requirements Planning

P. 296

CHAPTER 15 Industry Effect on MRP 275

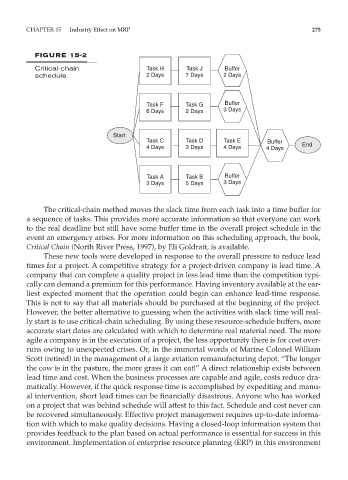

FIGURE 15-2

Critical-chain Task H Task J Buffer

schedule. 2 Days 7 Days 2 Days

Task F Task G Buffer

6 Days 2 Days 3 Days

Start

Task C Task D Task E Buffer

4 Days 3 Days 4 Days 4 Days End

Task A Task B Buffer

3 Days 5 Days 3 Days

The critical-chain method moves the slack time from each task into a time buffer for

a sequence of tasks. This provides more accurate information so that everyone can work

to the real deadline but still have some buffer time in the overall project schedule in the

event an emergency arises. For more information on this scheduling approach, the book,

Critical Chain (North River Press, 1997), by Eli Goldratt, is available.

These new tools were developed in response to the overall pressure to reduce lead

times for a project. A competitive strategy for a project-driven company is lead time. A

company that can complete a quality project in less lead time than the competition typi-

cally can demand a premium for this performance. Having inventory available at the ear-

liest expected moment that the operation could begin can enhance lead-time response.

This is not to say that all materials should be purchased at the beginning of the project.

However, the better alternative to guessing when the activities with slack time will real-

ly start is to use critical-chain scheduling. By using these resource-schedule buffers, more

accurate start dates are calculated with which to determine real material need. The more

agile a company is in the execution of a project, the less opportunity there is for cost over-

runs owing to unexpected crises. Or, in the immortal words of Marine Colonel William

Scott (retired) in the management of a large aviation remanufacturing depot, “The longer

the cow is in the pasture, the more grass it can eat!” A direct relationship exists between

lead time and cost. When the business processes are capable and agile, costs reduce dra-

matically. However, if the quick response time is accomplished by expediting and manu-

al intervention, short lead times can be financially disastrous. Anyone who has worked

on a project that was behind schedule will attest to this fact. Schedule and cost never can

be recovered simultaneously. Effective project management requires up-to-date informa-

tion with which to make quality decisions. Having a closed-loop information system that

provides feedback to the plan based on actual performance is essential for success in this

environment. Implementation of enterprise resource planning (ERP) in this environment