Page 83 - Pipeline Risk Management Manual Ideas, Techniques, and Resources

P. 83

4161

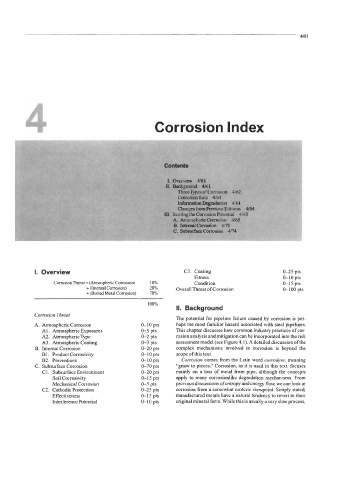

Corrosion Index

1. Overview C3. Coating 0-25 pts

Fitness 0-10 pts

CorrosionThreat = (Atmospheric Corrosion) 10% Condition 0-15 pts

+(Internal Corrosion) 20% Overall Threat of Corrosion 0-100 pts

+ (Buried Metal Corrosion) 70%

100%

II. Background

Corrosion Threat

The potential for pipeline failure caused by corrosion is per-

A. Atmospheric Corrosion 0-10 pts haps the most familiar hazard associated with steel pipelines.

A1 . Atmospheric Exposures 0-5 pts This chapter discusses how common industry practices of cor-

A2. Atmospheric Type 0-2 pts rosion analysis and mitigation can be incorporated into the risk

A3. Atmospheric Coating 0-3 pts assessment model (see Figure 4.1). A detailed discussion of the

B. Internal Corrosion 0-20 pts complex mechanisms involved in corrosion is beyond the

B1. Product Corrosivity 0-10 pts scope of this text.

B2. Preventions 0-10 pts Corrosion comes from the Latin word corrodere, meaning

C. Subsurface Corrosion 0-70 pts “gnaw to pieces.” Corrosion, as it is used in this text, focuses

C 1. Subsurface Environment 0-20 pts mainly on a loss of metal from pipe, although the concepts

Soil Corrosivity 0-15 pts apply to many corrosionlike degradation mechanisms. From

Mechanical Corrosion 0-5 pts previous discussions of entropy and energy flow, we can look at

C2. Cathodic Protection 0-25 pts corrosion from a somewhat esoteric viewpoint. Simply stated,

Effectiveness 0-15 pts manufactured metals have a natural tendency to revert to their

Interference Potential 0-10 pts original mineral form. While this is usually a very slow process,