Page 81 - Pipeline Risk Management Manual Ideas, Techniques, and Resources

P. 81

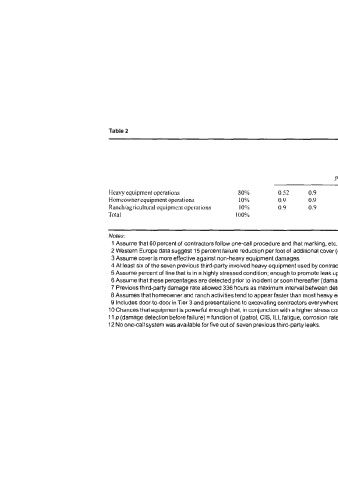

Table 2

p (ofleuk

huppening

p (equipment ufrer

powerjul activity is

p (event) = 1 -p (interruption) p (high stress) enough) proximal)

Heavy equipment operations 80% 0.52 0.9 0.95 0.85 0.95 0.7 0.5 0.9 9.05%

Homeowner equipment operations 10% 0.9 0.9 0.95 0.85 0.7 0.9 0.5 0.3 0.62%

Ranch/agricultural equipment operations 10% 0.9 0.9 0.95 0.85 0.9 0.8 0.5 0.6 1.41%

Total 100% 11.08%

5 10

Notes:

1 Assume that 60 percent of contractors follow one-call procedure and that marking, etc., is 80 percent effective.

2 Western Europe data suggest 15 percent failure reduction per foot of additional cover (over "normal" depth).

3 Assume cover is more effective against non-heavy equipment damages.

4 At least six of the seven previous third-party involved heavy equipment used by contractors.

5 Assume percent of line that is in a highly stressed condition; enough to promote leak upon moderate damage.

6 Assume that these percentages are detected prior to incident or soon thereafter (damage assessment opportunity).

7 Previous third-party damage rate allowed 336 hours as maximum interval between detection opportunities; new is 24.60, or 168 hours maximum

8 Assumes that homeowner and ranch activities tend to appear faster than most heavy equipment projects.

9 Includes door-to-door in Tier 3 and presentations to excavating contractors everywhere.

10 Chances that equipment is powerful enough that, in conjunction with a higher stress condition in the pipe wall, immediate rupture is likely.

11 p (damage detection before failure) =function of (patrol, CIS. ILI. fatigue, corrosion rate, stress level).

12 No one-call system was available for five out of seven previous third-party leaks.