Page 238 - Pipelines and Risers

P. 238

Installation Design 21 1

stresdcollapse will converge. Hence the wall-thickness requirements should be less for dense

oil than for gas.

12.6.3 Implication to Installation, Testing and Operation

What are the implications of changing from a 3 medium to a 2 medium pipeline? All phases

of the pipeline installation, testing and operation will be affected by providing a limitation to

the contents density and the minimum pressure. The principal issues for each phase are:

Installation: The pipeline will need a facility to free flood during installation and cancel any

differential pressure in this phase. Although the pipeline wall-thick-ness may be significantly

reduced, the submerged pipe weight is still increased and the pipelay tensions can be-come

too high for the present laybarge capacity. This phenomena is true in comparison with lines

installed dry in shallow water but not deepwater.

Testing: The pipeline internal pressure must stay above a design minimum, so although the

pressure testing will be unaffected the drying the pipeline with ambient pressure hot air and/or

vacuum drying will not be possible. Pre-commissioning would have to employ methanol

slugs or similar followed by the product at operational pressure.

Operation: Throughout the production life, a minimum operating pressure must be

maintained otherwise the pipeline will collapse. In practice this would require a minimum

pressure assurance system, such as having isolation valves, which would prevented the

pipeline pressure dropping below a specified minimum.

The implications for both the testing and operation phases, although significant, are not

insurmountable with existing technology and practices. On the other hand, the impact on

installation is significant and is what this section will focus on.

12.6.4 Installing Free Flooding Pipelines

Installing pipelines dry has been logically adopted as the lay tensions can be kept relatively

low and there is a large margin to be gained between with the increased submerged weight

during operation (for stability purposes). This logic is sound in shallow water but can not be

extrapolated to depths in excess of 1000m. The required wall-thickness of an airfilled pipeline

becomes so large that the associated submerged weight will require lay tensions significantly

greater than present lay barge capacity.

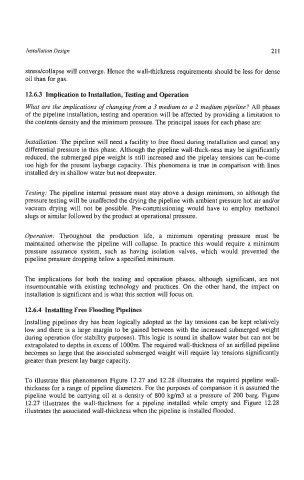

To illustrate this phenomenon Figure 12.27 and 12.28 illustrates the required pipeline wall-

thickness for a range of pipeline diameters. For the purposes of comparison it is assumed the

pipeline would be carrying oil at a density of 800 kg/m3 at a pressure of 200 barg. Figure

12.27 illustrates the wall-thickness for a pipeline installed while empty and Figure 12.28

illustrates the associated wall-thickness when the pipeline is installed flooded.