Page 213 - Plant design and economics for chemical engineers

P. 213

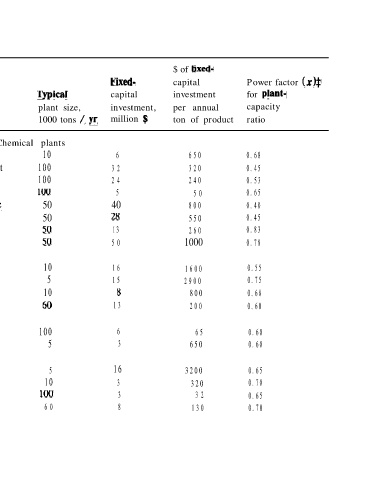

TABLE 19

Capital-cost data for processing plants (i990)t

$ of fixed-

Fiied- capital Power factor (x)$

PKUdUCt ljpical capital investment for plant-

Or plant size, investment, per annual capacity

Pro== Process remarks 1000 tons / yr million .$ ton of product ratio

Chemical plants

Acetic acid CHsOH and CO-catalytic 10 6 650 0.68

Acetone Propylene-copper chloride catalyst 100 3 2 320 0.45

Ammonia Steam reforming 100 2 4 240 0.53

Ammonium nitrate Ammonia and nitric acid 100 5 5 0 0.65

Butanof Propylene, CO, and H,O-catalytic 50 40 800 0.40

Chlorine Electrolysis of NaCl 50 28 550 0.45

Ethylene Refinery gases 50 13 260 0.83

Ethylene oxide Ethylene-catalytic 50 5 0 1000 0.78

Formaldehyde

(37%) Methanol-catalytic 10 16 1600 0.55

Glycol Ethylene and chlorine 5 15 2900 0.75

Hydrofluoric acid Hydrogen fluoride and H,O 10 8 800 0.68

Methanol CO,, natural gas, and steam 60 13 200 0.60

Nitric acid

(high strength) Ammonia-catalytic 100 6 65 0.60

Phosphoric acid Calcium phosphate and H,SO, 5 3 650 0.60

Polyethylene

(high density) Ethylene-catalytic 5 16 3200 0.65

Propylene Refinery gases 10 3 320 0.70

Sulfuric acid Sulfur-catalytic 100 3 3 2 0.65

Urea Ammonia and CO, 6 0 8 130 0.70