Page 214 - Plant design and economics for chemical engineers

P. 214

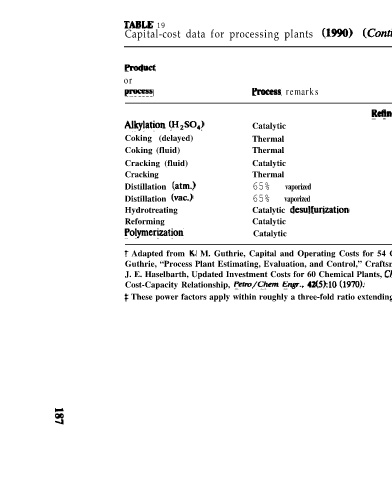

TABLE 19

Capital-cost data for processing plants @!90) (Continued)

Fixed- sofn!ted- Power factor (x)s

ROdUCi Typical =Pm Crrpitd for plant-

or plant size, investmenf investment =padty

P-s Pmcess remarks lOOObbI/day miMon$ per bbl / day ratio

ReRnmyunits

Alkylation (H,SO,) Catalytic 10 19 1900 0.60

Coking (delayed) Thermal 10 26 2600 0.38

Coking (fluid) Thermal 10 16 MOO 0.42

Cracking (fluid) Catalytic 10 16 1600 0.70

Cracking Thermal 10 5 500 0.70

Distillation (atm.) 65% vaporized 100 32 3m 0.90

Distillation fvac.) 65% vaporized 100 19 200 0.70

Hydrotreating Catalytic desulfitrization 10 3 320 0.65

Reforming Catalytic 10 29 0.60

Polytnerization Catalytic 10 5 0.58

t Adapted from K. M. Guthrie, Capital and Operating Costs for 54 Chemical Processes, Chem. Eng.. 11(13):140 f.June 15, 1970) and K. M.

Guthrie, “Process Plant Estimating, Evaluation, and Control,” Craftsman Book Company of America, Solana Beach, California. 1974. See also

J. E. Haselbarth, Updated Investment Costs for 60 Chemical Plants, C/rem. Eng., 74(25):214 (Dec. 4, 1967) and D. Drayer, How to Estimate Plant

Cost-Capacity Relationship, Perru/Chem Engr., 42(5):10 (1970).

$ These power factors apply within roughly a three-fold ratio extending either way from the plant size as given.