Page 166 - Plastics Engineering

P. 166

Mechanical Behaviour of Plastics 149

shows the triaxial stresses which exist at the tip of a notch. It is this triaxiality

which promotes brittleness in the material. Therefore, in practice one should

avoid abrupt changes in section, holes, notches, keyways etc at critical, highly

stressed areas in a moulding.

In the laboratory the impact behaviour of a material could be examined by

testing plain samples, but since brittle failures are of particular interest it is

more useful to ensure that the stress system is triaxial. This may be achieved

most conveniently by means of a notch in the sample. The choice of notch

depth and tip radius will affect the impact strengths observed. A sharp notch

is usually taken as 0.25 mm radius and a blunt notch as 2 mm radius.

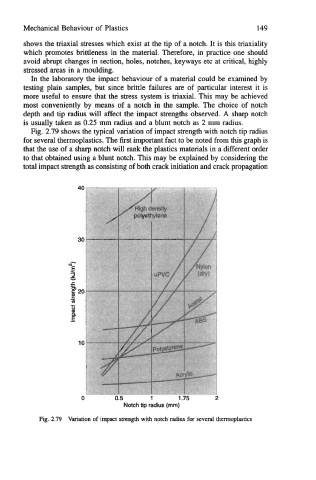

Fig. 2.79 shows the typical variation of impact strength with notch tip radius

for several thermoplastics. The first important fact to be noted from this graph is

that the use of a sharp notch will rank the plastics materials in a different order

to that obtained using a blunt notch. This may be explained by considering the

total impact strength as consisting of both crack initiation and crack propagation

I

40

c polyethylene

30

N- E

2

c

P 20

g!

e

u)

'G

mp

-

E

10

-

-

0 ( 5 1 1.75

Notch tip radius (mm)

Fig. 2.79 Variation of impact strength with notch radius for several thermoplastics