Page 168 - Plastics Engineering

P. 168

Mechanical Behaviour of Plastics 151

(wet 1 I I n dch

*

4

(dry)

Nylon

Ac IlC

0

-LO - 20 0 20 40

I

Test temperature (OC

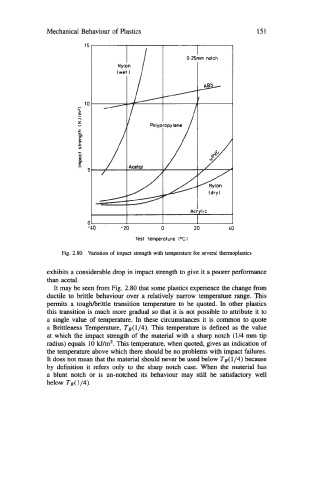

Fig. 2.80 Variation of impact strength with temperature for several thermoplastics

exhibits a considerable drop in impact strength to give it a poorer performance

than acetal.

It may be seen from Fig. 2.80 that some plastics experience the change from

ductile to brittle behaviour over a relatively narrow temperature range. This

permits a toughhrittle transition temperature to be quoted. In other plastics

this transition is much more gradual so that it is not possible to attribute it to

a single value of temperature. In these circumstances it is common to quote

a Brittleness Temperature, T~(1/4). This temperature is defined as the value

at which the impact strength of the material with a sharp notch (1/4 mm tip

radius) equals 10 kJ/m2. This temperature, when quoted, gives an indication of

the temperature above which there should be no problems with impact failures.

It does not mean that the material should never be used below TB( 1 /4) because

by definition it refers only to the sharp notch case. When the material has

a blunt notch or is un-notched its behaviour may still be satisfactory well

below T~(1/4).