Page 170 - Plastics Engineering

P. 170

Mechanical Behaviour of Plastics 153

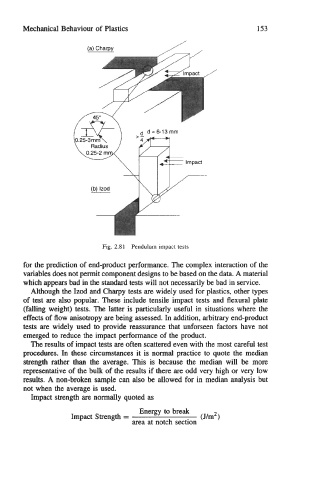

Fig. 2.81 Pendulum impact tests

for the prediction of end-product performance. The complex interaction of the

variables does not permit component designs to be based on the data. A material

which appears bad in the standard tests will not necessarily be bad in service.

Although the Izod and Chqy tests are widely used for plastics, other types

of test are also popular. These include tensile impact tests and flexural plate

(falling weight) tests. The latter is particularly useful in situations where the

effects of flow anisotropy are being assessed. In addition, arbitrary end-product

tests are widely used to provide reassurance that unforseen factors have not

emerged to reduce the impact performance of the product.

The results of impact tests are often scattered even with the most careful test

procedures. In these circumstances it is normal practice to quote the median

strength rather than the average. This is because the median will be more

representative of the bulk of the results if there are odd very high or very low

results. A non-broken sample can also be allowed for in median analysis but

not when the average is used.

Impact strength are normally quoted as

Energy to break

Impact Strength = (J/m2)

area at notch section