Page 167 - Plastics Engineering

P. 167

150 Mechanical Behaviour of Plastics

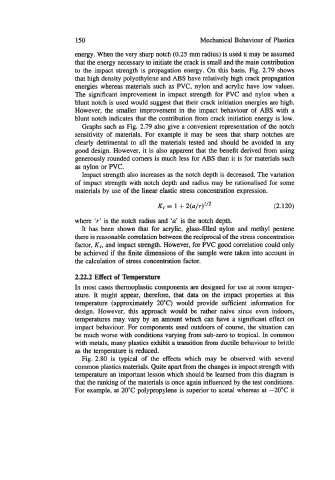

energy. When the very sharp notch (0.25 mm radius) is used it may be assumed

that the energy necessary to initiate the crack is small and the main contribution

to the impact strength is propagation energy. On this basis, Fig. 2.79 shows

that high density polyethylene and ABS have relatively high crack propagation

energies whereas materials such as PVC, nylon and acrylic have low values.

The significant improvement in impact strength for PVC and nylon when a

blunt notch is used would suggest that their crack initiation energies are high.

However, the smaller improvement in the impact behaviour of ABS with a

blunt notch indicates that the contribution from crack initiation energy is low.

Graphs such as Fig. 2.79 also give a convenient representation of the notch

sensitivity of materials. For example it may be seen that sharp notches are

clearly detrimental to all the materials tested and should be avoided in any

good design. However, it is also apparent that the benefit derived from using

generously rounded comers is much less for ABS than it is for materials such

as nylon or PVC.

Impact strength also increases as the notch depth is decreased. The variation

of impact strength with notch depth and radius may be rationalised for some

materials by use of the linear elastic stress concentration expression.

Kt = 1 + 2(u/r)”2 (2.120)

where ‘r’ is the notch radius and ‘d is the notch depth.

It has been shown that for acrylic, glass-filled nylon and methyl pentene

there is reasonable correlation between the reciprocal of the stress concentration

factor, Kt, and impact strength. However, for PVC good correlation could only

be achieved if the finite dimensions of the sample were taken into account in

the calculation of stress concentration factor.

2.22.2 Effect of Temperature

In most cases thermoplastic components are designed for use at room temper-

ature. It might appear, therefore, that data on the impact properties at this

temperature (approximately 20°C) would provide sufficient information for

design. However, this approach would be rather naive since even indoors,

temperatures may vary by an amount which can have a significant effect on

impact behaviour. For components used outdoors of course, the situation can

be much worse with conditions varying from sub-zero to tropical. In common

with metals, many plastics exhibit a transition from ductile behaviour to brittle

as the temperature is reduced.

Fig. 2.80 is typical of the effects which may be observed with several

common plastics materials. Quite apart from the changes in impact strength with

temperature an important lesson which should be learned from this diagram is

that the ranking of the materials is once again influenced by the test conditions.

For example, at 20°C polypropylene is superior to acetal whereas at -20°C it