Page 142 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 142

A New Do11ain and lore Process Models 117

1

2

~(-rmc) + 1

(4-26)

1

-m,D- tan- (-rmJ = -n

Equation (4-26) gives two equations in two unknowns: k, and m,.

A closed form solution to this problem is not straightforward (and

probably not possible, at least for me) so a numerical solution based

on a two-dimensional minimization (using fminsearch in Matlab)

yielded the following values for g = 2.5, 'f = 10, D = 8, k, = 1.06, fc =

0.039. Had we tried the same approach for PI control there would still

be two equations but now there would be three unknowns.

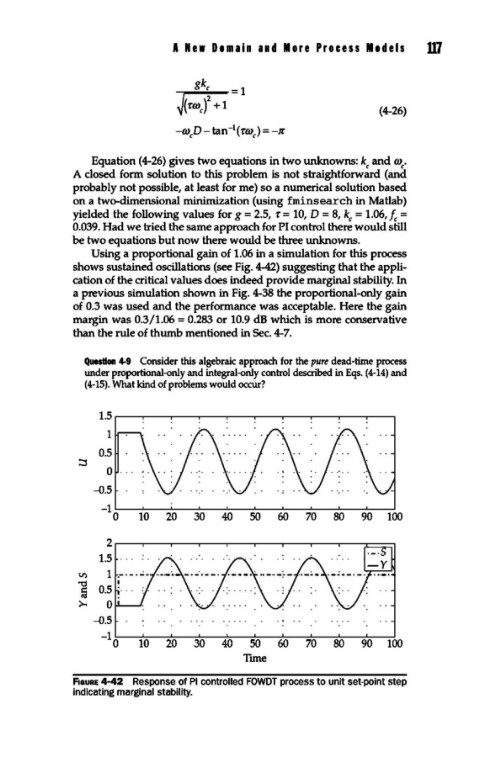

Using a proportional gain of 1.06 in a simulation for this process

shows sustained oscillations (see Fig. 4-42) suggesting that the appli-

cation of the critical values does indeed provide marginal stability. In

a previous simulation shown in Fig. 4-38 the proportional-only gain

of 0.3 was used and the performance was acceptable. Here the gain

margin was 0.3/1.06 = 0.283 or 10.9 dB which is more conservative

than the rule of thumb mentioned in Sec. 4-7.

Question 4-9 Consider this algebraic approach for the pure dead-time process

under proportional-only and integral-only control described in Eqs. (4-14) and

(4-15). What kind of problems would occur?

1.5

1

0.5

::::::1

0

-0.5

10 20 30 40 50 60 70 80 90 100

2

1.5

U')

"'0

ij

>o 0

-0.5 . . . . .... .. . ...

-1

0 10 20 30 40 50 60 70 80 90 100

Tune

fiGURE 4-42 Response of PI controlled FOWDT process to unit set-point step

indicating marginal stability.