Page 137 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 137

112 Chapter Four

0.7

0.6 . . . ...

0.5

0.4

:::s

0.3 ..

0.2

0.1

0

0 10 20 30 40 50 60 70 80 90 100

2

1.5

V)

"'0

c:: 1 -·-·- --·

<U

>-

40 50 60 70 80 90 100

Time

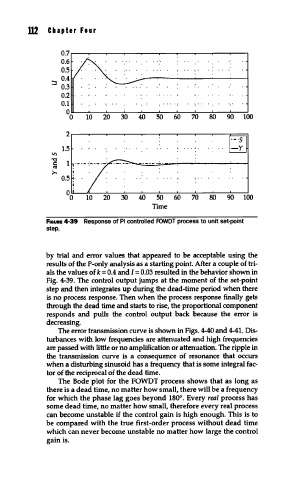

F•auRE 4-39 Response of PI controlled FOWDT process to unit set-point

step.

by trial and error values that appeared to be acceptable using the

results of the P-only analysis as a starting point. After a couple of tri-

als the values of k = 0.4 and I= 0.03 resulted in the behavior shown in

Fig. 4-39. The control output jumps at the moment of the set-point

step and then integrates up during the dead-time period when there

is no process response. Then when the process response finally gets

through the dead time and starts to rise, the proportional component

responds and pulls the control output back because the error is

decreasing.

The error transmission curve is shown in Figs. 4-40 and 4-41. Dis-

turbances with low frequencies are attenuated and high frequencies

are passed with little or no amplification or attenuation. The ripple in

the transmission curve is a consequence of resonance that occurs

when a disturbing sinusoid has a frequency that is some integral fac-

tor of the reciprocal of the dead time.

The Bode plot for the FOWDT process shows that as long as

there is a dead time, no matter how small, there will be a frequency

for which the phase lag goes beyond 180°. Every real process has

some dead time, no matter how small, therefore every real process

can become unstable if the control gain is high enough. This is to

be compared with the true first-order process without dead time

which can never become unstable no matter how large the control

gain is.