Page 166 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 166

Matrices and Higher-Order Process Models 141

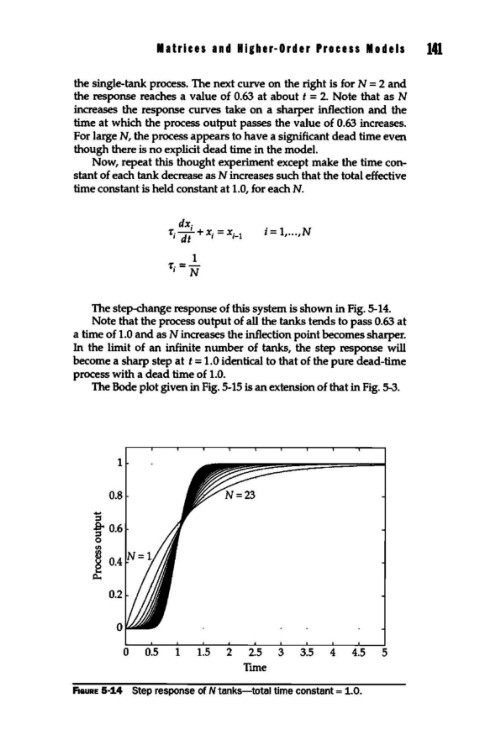

the single-tank process. The next curve on the right is for N = 2 and

the response reaches a value of 0.63 at about t = 2. Note that as N

increases the response curves take on a sharper inflection and the

time at which the process output passes the value of 0.63 increases.

For large N, the process appears to have a significant dead time even

though there is no explicit dead time in the model.

Now, repeat this thought experiment except make the time con-

stant of each tank decrease as N increases such that the total effective

time constant is held constant at 1.0, for each N.

dx.

1

T--+x. =x. i = 1, ... ,N

I df I 1- 1

1

T-=-

1 N

The step-change response of this system is shown in Fig. 5-14.

Note that the process output of all the tanks tends to pass 0.63 at

a time of 1.0 and as N increases the inflection point becomes sharper.

In the limit of an infinite number of tanks, the step response will

become a sharp step at t = 1.0 identical to that of the pure dead-time

process with a dead time of 1.0.

The Bode plot given in Fig. 5-15 is an extension of that in Fig. 5-3.

1

0.8

.....

=

t 0.6

<I)

~

2 o.4

Q..,

0.2

0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

Tune

F1auRE 5-14 Step response of N tanks-total time constant= 1.0.