Page 171 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 171

146 C h a p t e r S ix

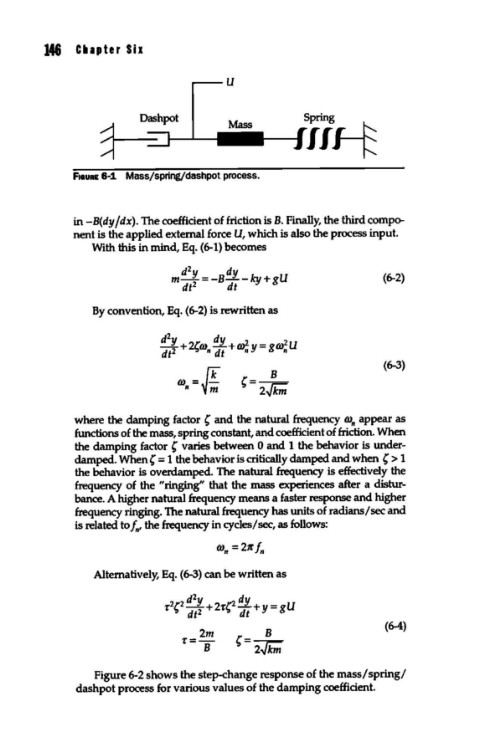

u

Dashpot

F1auRE 6-1 Massjspring,tdashpot process.

in -B(dy Jdx). The coefficient of friction is B. Finally, the third compo-

nent is the applied external force U, which is also the process input.

With this in mind, Eq. (6-1) becomes

2

d y dy

m dt2 = -8-;u- ky + gU (6-2)

By convention, Eq. (6-2) is rewritten as

d2y dy - 2

di2 + 2{co, dt+ ~ y- gco, U

co= rr B (6-3)

" vm {= 2Ji(m

where the damping factor { and the natural frequency C0 appear as

11

functions of the mass, spring constant, and coefficient of friction. When

the damping factor { varies between 0 and 1 the behavior is under-

damped. When { = 1 the behavior is critically damped and when { > 1

the behavior is overdamped. The natural frequency is effectively the

frequency of the "ringing'' that the mass experiences after a distur-

bance. A higher natural frequency means a faster response and higher

frequency ringing. The natural frequency has units of radians/ sec and

is related to f,, the frequency in cycles/ sec, as follows:

co"= 21r /,

Alternatively, Eq. ( 6-3) can be written as

(6-4)

2m B

T=- {= 2Ji;i

8

Figure 6-2 shows the step-change response of the mass/spring/

dashpot process for various values of the damping coefficient.