Page 218 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 218

192 Chapter Seven

which would have periods of 10.0 sec or more, there appears to be no

resonance because the amplitude is nearly unity. This suggests that

for these low frequencies, the jacket temperature variations are passed

through the tube unattenuated. Thus, for low jacket temperature fre-

quencies, the tube is long enough to cause the outlet temperature to

have the same amplitude as the jacket temperature.

7-6 Control of the Tubular Energy Exchanger

The open loop step-change response and the Bode plot suggest that there

should not be too much trouble if feedback control is attempted. The

large-diameter tubular energy exchanger has some idiosyncrasies but

the total phase lag varies about 90° (why?-because, despite the dis-

tributed nature of the process, it is still basically first order).

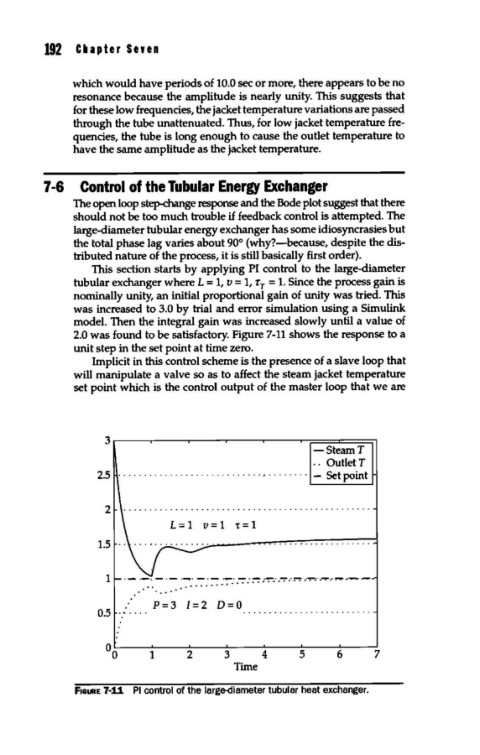

This section starts by applying PI control to the large-diameter

tubular exchanger where L = 1, v = 1, rr = 1. Since the process gain is

nominally unity, an initial proportional gain of unity was tried. This

was increased to 3.0 by trial and error simulation using a Simulink

model. Then the integral gain was increased slowly until a value of

2.0 was found to be satisfactory. Figure 7-11 shows the response to a

unit step in the set point at time zero.

Implicit in this control scheme is the presence of a slave loop that

will manipulate a valve so as to affect the steam jacket temperature

set point which is the control output of the master loop that we are

3r---~--~----~--~----~==~==~

-SteamT

.. OutletT

2.5 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 ° 0 0 0 0 0 0 0 0 , 0 0 ° 0 0 0 0 0 _ Set point

2

L=1 v=1 t=1

1

.•·•••••r

P=3 1=2 D=O

0.5 -· ....

1 2 3 4 5 6 7

Time

F1auRE 7-11 PI control of the large-diameter tubular heat exchanger.