Page 220 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 220

194 Chapter Seven

1.4 r-.........,..-~-~---"'T"----r--~~---;:=t::=:.====;J

-Steam T

.. OutletT

1.2

- Setpoint

1~-----.~ .. ~.----------------------------~

0.8

0.6 P = 1 I= 10 D = 0

0.4

0.2 ~

0

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

Time

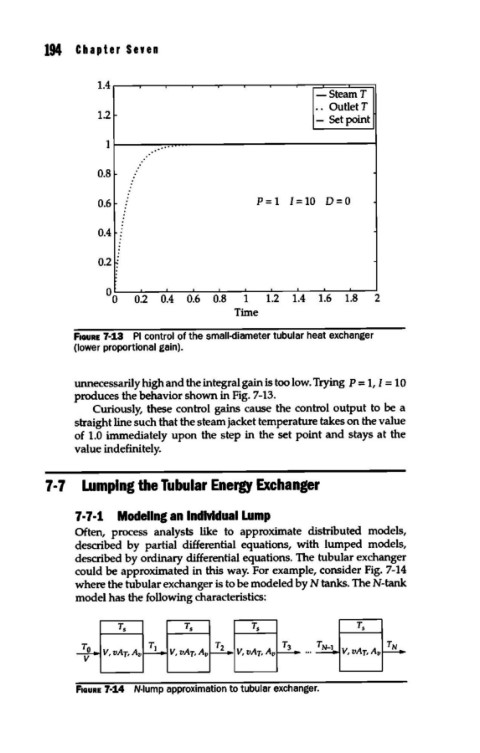

FIGURE 7-13 PI control of the small-diameter tubular heat exchanger

(lower proportional gain).

unnecessarily high and the integral gain is too low. Trying p = 1, I = 10

produces the behavior shown in Fig. 7-13.

Curiously, these control gains cause the control output to be a

straight line such that the steam jacket temperature takes on the value

of 1.0 immediately upon the step in the set point and stays at the

value indefinitely.

7 • 7 Lumping the Tubular Energy Exchanger

7 · 7 ·1 Modeling an Individual Lump

Often, process analysts like to approximate distributed models,

described by partial differential equations, with lumped models,

described by ordinary differential equations. The tubular exchanger

could be approximated in this way. For example, consider Fig. 7-14

where the tubular exchanger is to be modeled by N tanks. TheN-tank

model has the following characteristics:

FIGURE 7-14 N-lump approximation to tubular exchanger.