Page 219 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 219

Distributed Processes 193

going to key on. The dynamics of the slave loop are considered to be

so much faster than those of the liquid temperature control loop that

they can be neglected. This master I slave configuration is a cascade

control structure and will be dealt with in Chap. 11.

At time zero, the step in the set point causes the proportional

component of the control algorithm to jump to 3.0 (which makes

sense because the proportional gain is 3.0). As the outlet temperature

starts to respond, the proportional component backs off. At t = 1.0 the

initial contents of the tube have passed through the exchanger.

Although there is a delay for the liquid to pass through the tube, all

of the liquid sees the step in the jacket temperature immediately so

there is no dead-time effect. For t > 1. 0 the tube will contain material

that has entered the exchanger after the set point was stepped and the

outlet temperature will back off slightly with an associated response

of the proportional component. All this time, the integral component

has been slowly working to bring the outlet temperature near the set

point. The reader can try other control gain combinations by modify-

ing the Matlab script that generated Fig. 7-11.

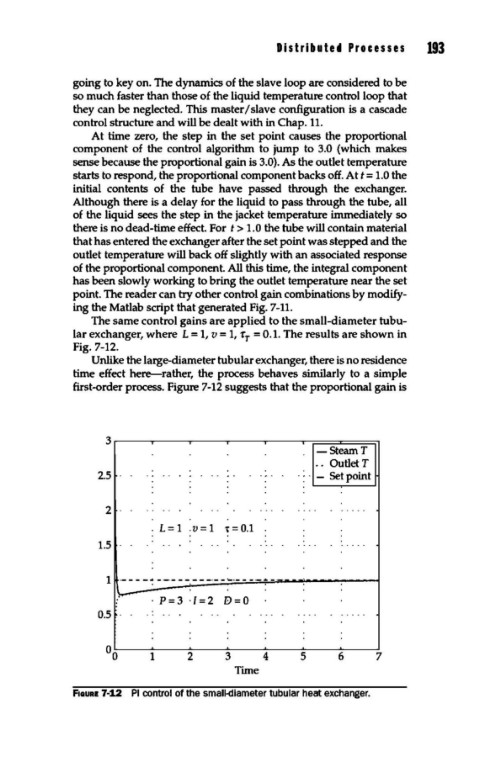

The same control gains are applied to the small-diameter tubu-

lar exchanger, where L = 1, v = 1, rr = 0.1. The results are shown in

Fig. 7-12.

Unlike the large-diameter tubular exchanger, there is no residence

time effect here-rather, the process behaves similarly to a simple

first-order process. Figure 7-12 suggests that the proportional gain is

3r---,---.----.----.----~==~==~

-Steam T

0

.. OutletT

2.5 0 : 0 - Set point

2

L = 1 ° v = 1 t = 0.1

1.5

1 --- - - ... - - -- -- --- - -·- - - • -

~0 0

o P = 3 I = 2 E> = 0

;· o

0.5

1 2 3 4 5 6 7

Time

F1aURE 7-12 PI control of the small-diameter tubular heat exchanger.