Page 216 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 216

190 Chapter Seven

0.8

5'

:2. 0.6

cu

"'0

.a 0.4

:.:1

a..

~

1 2 3 4 5 6 7 8 9 10

0

-20 .. . . ... .

- -40 ·I

~

~ -60

!IS

..c

rl.. -80

-100

-120

0 1 2 3 4 5 6 7 8 9 10

Frequency (Hz)

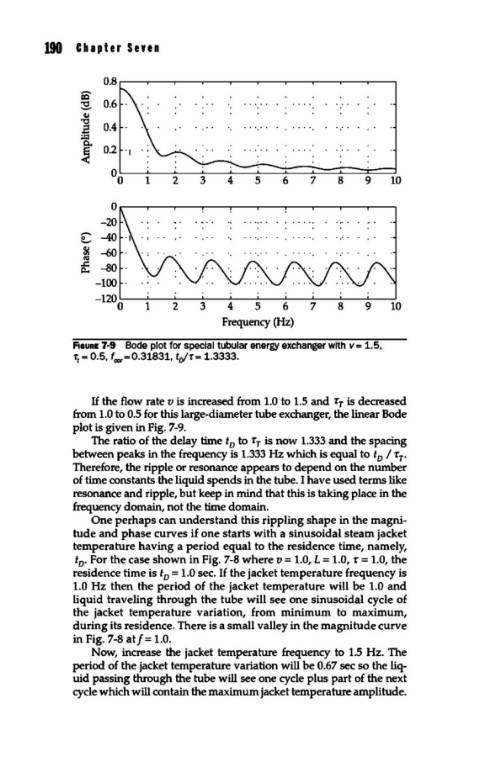

fiGURE 7-9 Bode plot for special tubular energy exchanger with v = 1.5,

rt = 0.5, fcor=0.31831, tofr= 1.3333.

If the flow rate v is increased from 1.0 to 1.5 and r 1 is decreased

from 1.0 to 0.5 for this large-diameter tube exchanger, the linear Bode

plot is given in Fig. 7-9.

The ratio of the delay time t to T 1 is now 1.333 and the spacing

0

between peaks in the frequency is 1.333 Hz which is equal to t I -r .

0 1

Therefore, the ripple or resonance appears to depend on the number

of time constants the liquid spends in the tube. I have used terms like

resonance and ripple, but keep in mind that this is taking place in the

frequency domain, not the time domain.

One perhaps can understand this rippling shape in the magni-

tude and phase curves if one starts with a sinusoidal steam jacket

temperature having a period equal to the residence time, namely,

t • For the case shown in Fig. 7-8 where v = 1.0, L = 1.0, 'r = 1.0, the

0

residence time is t = 1.0 sec. If the jacket temperature frequency is

0

1.0 Hz then the period of the jacket temperature will be 1.0 and

liquid traveling through the tube will see one sinusoidal cycle of

the jacket temperature variation, from minimum to maximum,

during its residence. There is a small valley in the magnitude curve

in Fig. 7-8 atf= 1.0.

Now, increase the jacket temperature frequency to 1.5 Hz. The

period of the jacket temperature variation will be 0.67 sec so the liq-

uid passing through the tube will see one cycle plus part of the next

cycle which will contain the maximum jacket temperature amplitude.