Page 389 - Practical Design Ships and Floating Structures

P. 389

364

But there are alternatives and the future of Laser-welding in that respect is just beginning: There are

the Nd-Yag-Lasers and there will be the Diode Lasers. Here the wave length of the light is only 1,06

pm or slightly less. This makes the use of fibre-optics possible and consequently the beam handling is

reduced to a flexible strand of fibres which easily can be fixed to a robot arm. In addition Diode Lasers

will be very small as compared to what we are

Top lid ( . )

Heat *Ink ( I Laser bar Cyl. mlsro lens

Cyllndrlcal mlcm lenses for dlvargencs concentrallng and parallel beam

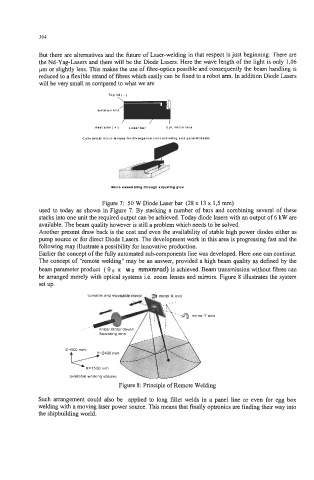

Figure 7: 50 W Diode Laser bar (28 x 13 x 1,s mm)

used to today as shown in Figure 7. By stacking a number of bars and combining several of these

stacks into one unit the required output can be achieved. Today diode lasers with an output of 6 kW are

available. The beam quality however is still a problem which needs to be solved.

Another present draw back is the cost and even the availability of stable high power diodes either as

pump source or for direct Diode Lasers. The development work in this area is progressing fast and the

following may illustrate a possibility for innovative production.

Earlier the concept of the fully automated sub-components line was developed. Here one can continue.

The concept of "remote welding" may be an answer, provided a high beam quality as defined by the

beam parameter product ( 8 0 x w 0 mmxmrad) is achieved. Beam transmission without fibres can

be arranged merely with optical systems i.e. zoom lenses and mirrors. Figure 8 illustrates the system

set up.

turnable and moveable mirror - 3 mirmr X axis

-Q mirror Y ' axis

- - - - -r

linear motor dnv

focussing lens

available working volume

Figure 8: Principle of Remote Welding

Such arrangement could also be applied to long fillet welds in a panel line or even for egg box

welding with a moving laser power source. This means that finally optronics are finding their way into

the shipbuilding world.