Page 166 - Pressure Vessel Design Manual

P. 166

B

144 Pressure Vessel Design Manual

1-7~3

r

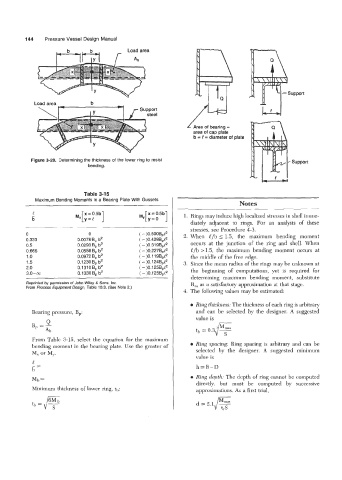

Load area

Ab

Load area b

Area of bearing =

area of cap plate

b = 0 = diameter of plate

Figure 3-28. Determining the thickness of the lower ring to resist Support

bending.

Table 3-15

Maximum Bending Moments in a Bearing Plate With Gussets

Notes

e

- 1. Rings may induce high localized stresses in shell imme-

b

diately adjacent to rings. For an analysis of these

stresses, see Procedure 4-3.

0 0 ( - )0.500Bp12 2. When l/b 5 1.5, the maximum bending moment

0.333 0.0078 B, b2 ( - )0.428~,e~ occurs at the junction of the ring and shell. When

0.5 0.0293 B, b2 ( - )0.319Bp12

0.666 0.0558 B, b2 ( - )0.227Bp12 l/b >1.5, the maximum bending moment occurs at

1 .o 0.0972 B, b2 (-)0.119Bp12 the middle of the free edge.

1.5 0.1230 B, b2 ( - )O. 1 24Bp12 3. Since the mean radius of the rings may be unknown at

2.0 0.1 31 0 B, b2 ( - )0.125BpE2 the beginning of computations, yet is required for

3.0-00 0.1330BP b2 ( - )0.125Bp12

determining maximum bending moment, substitute

Reprinted by permission of John Wiley & Sons, Inc. R, as a satisfactory approximation at that stage.

From Process Equipment Design, Table 10.3. (See Note 2.)

4. The following values may be estimated:

e Ring thickness: The thickness of each ring is arbitrary

Bearing pressure, B,: and can be selected by the designer. A suggested

value is

Q

BP =Ab

From Table 3-15, select the equation for the maximum

bending moment in the bearing plate. Use the greater of Ring spacing: Ring spacing is arbitrary and can be

M, or M,. selected by the designer. A suggested minimum

value is

c

_-

b- h=B-D

M1, = Ring depth: The depth of ring cannot be computed

directly, but must be computed by successive

Minimum thickness of lower ring, th: approximations. As a first trial,