Page 169 - Pressure Vessel Design Manual

P. 169

Design of Vessel Supports 147

axis

I-

b axis

L Assume as 0.8P

for single gusset

M

F=-L

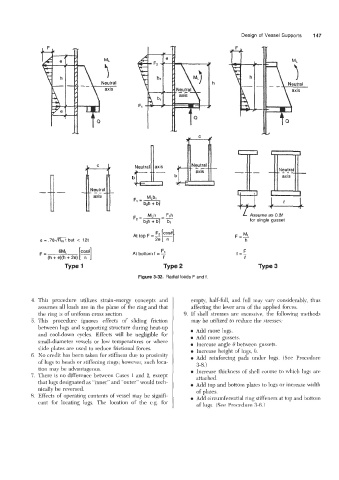

e = .78a but < 12t h

F

F= ~ML COS0 At bottom f = -2 f=- F

(h + e)(h + 2e) [T] 0 0

Type 2 Type 3

Figure 3-32. Radial loads F and f.

4. This procedure utilizes strain-energy concepts and empty, half-full, and f~dl may vary considerably, thus

assumes all loads are in the plane of the ring and that affecting the lever arm of the applied forces.

the ring is of uniform cross section. 9. If shell stresses are excessive, the following methods

5. This procedure ignores effects of sliding friction may be utilized to reduce the stresses:

between lugs and supporting structure during heat-up 0 Add more lugs.

and cool-down cycles. Effects will be negligible for 0 Add more gussets.

small-diameter vessels or low temperatures or where 0 Increase angle e between gussets.

slide plates are used to reduce frictional forces. 0 Increase height of lugs, 11.

6. No credit has been taken for stiffness due to proximity

of lugs to heads or stiffening rings; however, such loca- Add reinforcing pads under lugs. (See Procedure

3-8.)

tion may be advantageous.

7. There is no difference between Cases 1 and 2, except 0 Increase thickness of she11 course to which lugs are

that lugs designated as “inner” and “outer” would tech- attached .

nically be reversed. 0 Add top and bottom plates to lugs or increase width

of plates.

8. Effects of operating contents of vessel may be signifi- 0 Add circumferential ring stiffeners at top and bottom

cant for locating lugs. The location of the c.g. for

of lugs. (See Procedure 3-6.)