Page 204 - Pressure Vessel Design Manual

P. 204

182 Pressure Vessel Design Manual

Anchor Bolts

Anchor bolts are governed by one of the three following

load cases:

1. Longitudinal load: If Qo > QL, then no uplift occurs,

and the minimum number and size of anchor bolts

should be used.

If Qo < QL, then uplift does occur:

QL - Qo = load per bolt

.N

2. Shear: Assume the fNed saddle takes the entire shear

load.

FL

- = shear per bolt

N

3. Transverse load: This method of determining uplift

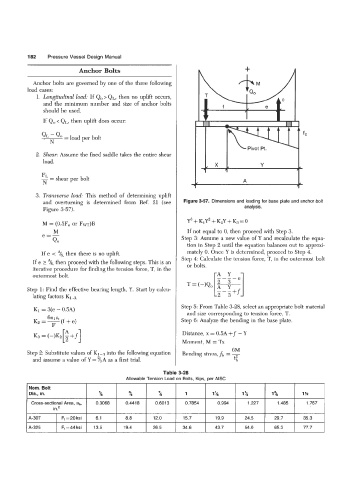

and overturning is determined from Ref. 21 (see Figure 3-57. Dimensions and loading for base plate and anchor bolt

Figure 3-57). analysis.

M = (0.5Fe or Fw)B Y3 + K,Y2 + KzY + K3 = 0

M If not equal to 0, then proceed with Step 3.

e=- Step 3: Assume a new value of Y and recalculate the equa-

Qo

tion in Step 2 until the equation balances out to approxi-

If e < "/6, then there is no uplift. mately 0. Once Y is determined, proceed to Step 4.

Step 4: Calculate the tension force, T, in the outermost bolt

If e 3 %, then proceed with the following steps. This is an or bolts.

iterative procedure for finding the tension force, T, in the

outermost bolt. I-A Y 1

Step 1: Find the effective bearing length, Y. Start by calcu-

lating factors K1a,

Step 5: From Table 3-28, select an appropriate bolt material

Ki = 3(e - 0.5A) and size corresponding to tension-force, T.

6nlat

(f + e)

Kz = - Step 6: Analyze the bending in the base plate.

F

Distance, x = 0.5A +f - Y

Moment, M = Tx

6M

Step 2: Substitute values of K1-3 into the following equation Bending stress,fb = -

and assume a value of Y = %A as a first trial. t"b

Allowable Tension Load on Bolts, Kips, per AlSC

~ Nom. Bolt

Dia., in. % t 2l 1 1% 1% 1% 1 'h

Cross-sectional Area, ab, 0.3068 0.441 8 0.6013 0.7854 0.994 1.227 1.485 1.767

in.'

A-307 Ft=20ksi 6.1 8.8 12.0 15.7 19.9 24.5 29.7 35.3

A-325 Ft=44ksi 13.5 19.4 26.5 34.6 43.7 54.0 65.3 77.7