Page 218 - Reciprocating Compressors Operation Maintenance

P. 218

2O4 Reciprocating Compressors: Operation and Maintenance

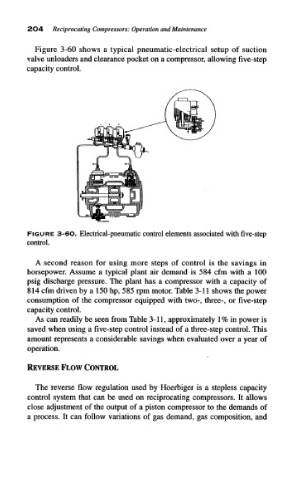

Figure 3-60 shows a typical pneumatic-electrical setup of suction

valve unloaders and clearance pocket on a compressor, allowing five-step

capacity control.

FIGURE 3-6O. Electrical-pneumatic control elements associated with five-step

control.

A second reason for using more steps of control is the savings in

horsepower. Assume a typical plant air demand is 584 cfm with a 100

psig discharge pressure. The plant has a compressor with a capacity of

814 cfm driven by a 150 hp, 585 rpm motor. Table 3-11 shows the power

consumption of the compressor equipped with two-, three-, or five-step

capacity control.

As can readily be seen from Table 3-11, approximately 1% in power is

saved when using a five-step control instead of a three-step control. This

amount represents a considerable savings when evaluated over a year of

operation.

The reverse flow regulation used by Hoerbiger is a stepless capacity

control system that can be used on reciprocating compressors. It allows

close adjustment of the output of a piston compressor to the demands of

a process. It can follow variations of gas demand, gas composition, and