Page 316 - Renewable Energy Devices and System with Simulations in MATLAB and ANSYS

P. 316

Power Conversion and Control for Fuel Cell Systems in Transportation 303

Accessory

loads

Hydrogen

Fuel cell CAP Propulsion

unit inverter

Air

Air input H input DC-DC

2

control control converter

Control

Fuel cell

controller Battery Propulsion

motor

Vm I Total

– Propulsion

I fc I ref

PI control system

+ Power controller

command

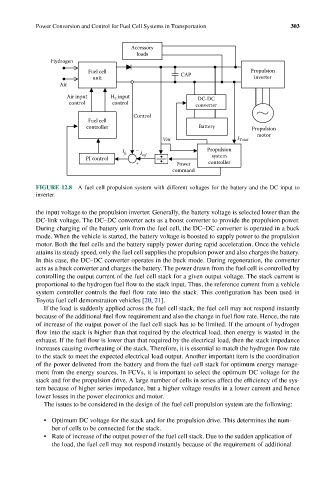

FIGURE 12.8 A fuel cell propulsion system with different voltages for the battery and the DC input to

inverter.

the input voltage to the propulsion inverter. Generally, the battery voltage is selected lower than the

DC-link voltage. The DC–DC converter acts as a boost converter to provide the propulsion power.

During charging of the battery unit from the fuel cell, the DC–DC converter is operated in a buck

mode. When the vehicle is started, the battery voltage is boosted to supply power to the propulsion

motor. Both the fuel cells and the battery supply power during rapid acceleration. Once the vehicle

attains its steady speed, only the fuel cell supplies the propulsion power and also charges the battery.

In this case, the DC–DC converter operates in the buck mode. During regeneration, the converter

acts as a buck converter and charges the battery. The power drawn from the fuel cell is controlled by

controlling the output current of the fuel cell stack for a given output voltage. The stack current is

proportional to the hydrogen fuel flow to the stack input. Thus, the reference current from a vehicle

system controller controls the fuel flow rate into the stack. This configuration has been used in

Toyota fuel cell demonstration vehicles [20, 21].

If the load is suddenly applied across the fuel cell stack, the fuel cell may not respond instantly

because of the additional fuel flow requirement and also the change in fuel flow rate. Hence, the rate

of increase of the output power of the fuel cell stack has to be limited. If the amount of hydrogen

flow into the stack is higher than that required by the electrical load, then energy is wasted in the

exhaust. If the fuel flow is lower than that required by the electrical load, then the stack impedance

increases causing overheating of the stack. Therefore, it is essential to match the hydrogen flow rate

to the stack to meet the expected electrical load output. Another important item is the coordination

of the power delivered from the battery and from the fuel cell stack for optimum energy manage-

ment from the energy sources. In FCVs, it is important to select the optimum DC voltage for the

stack and for the propulsion drive. A large number of cells in series affect the efficiency of the sys-

tem because of higher series impedance, but a higher voltage results in a lower current and hence

lower losses in the power electronics and motor.

The issues to be considered in the design of the fuel cell propulsion system are the following:

• Optimum DC voltage for the stack and for the propulsion drive. This determines the num-

ber of cells to be connected for the stack.

• Rate of increase of the output power of the fuel cell stack. Due to the sudden application of

the load, the fuel cell may not respond instantly because of the requirement of additional