Page 368 - Robot Builder's Bonanza

P. 368

CREATING X- Y SERVO JOINTS 337

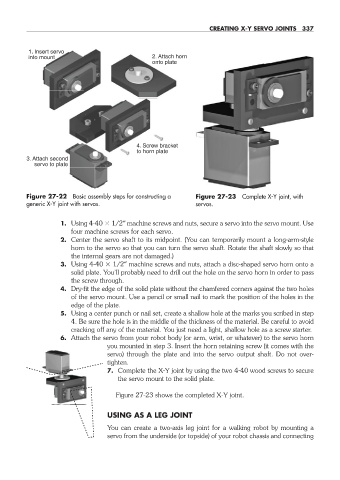

1. Insert servo

into mount 2. Attach horn

onto plate

4. Screw bracket

to horn plate

3. Attach second

servo to plate

Figure 27- 22 Basic assembly steps for constructing a Figure 27- 23 Complete X- Y joint, with

generic X- Y joint with servos. servos.

1. Using 4- 40 1/2″ machine screws and nuts, secure a servo into the servo mount. Use

four machine screws for each servo.

2. Center the servo shaft to its midpoint. (You can temporarily mount a long- arm- style

horn to the servo so that you can turn the servo shaft. Rotate the shaft slowly so that

the internal gears are not damaged.)

3. Using 4- 40 1/2″ machine screws and nuts, attach a disc- shaped servo horn onto a

solid plate. You’ll probably need to drill out the hole on the servo horn in order to pass

the screw through.

4. Dry- fit the edge of the solid plate without the chamfered corners against the two holes

of the servo mount. Use a pencil or small nail to mark the position of the holes in the

edge of the plate.

5. Using a center punch or nail set, create a shallow hole at the marks you scribed in step

4. Be sure the hole is in the middle of the thickness of the material. Be careful to avoid

cracking off any of the material. You just need a light, shallow hole as a screw starter.

6. Attach the servo from your robot body (or arm, wrist, or whatever) to the servo horn

you mounted in step 3. Insert the horn retaining screw (it comes with the

servo) through the plate and into the servo output shaft. Do not over-

tighten.

7. Complete the X- Y joint by using the two 4- 40 wood screws to secure

the servo mount to the solid plate.

Figure 27- 23 shows the completed X- Y joint.

USING AS A LEG JOINT

You can create a two- axis leg joint for a walking robot by mounting a

servo from the underside (or topside) of your robot chassis and connecting

27-chapter-27.indd 337 4/21/11 11:52 AM