Page 387 - Robot Builder's Bonanza

P. 387

356 EXPERIMENTING WITH ROBOTIC GRIPPERS

Pivot points

Palm Gripper

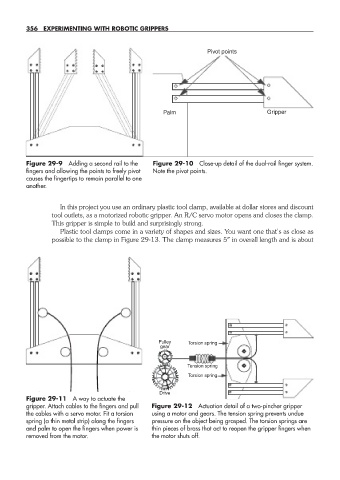

Figure 29- 9 Adding a second rail to the Figure 29- 10 Close- up detail of the dual- rail finger system.

fingers and allowing the points to freely pivot Note the pivot points.

causes the fingertips to remain parallel to one

another.

In this project you use an ordinary plastic tool clamp, available at dollar stores and discount

tool outlets, as a motorized robotic gripper. An R/C servo motor opens and closes the clamp.

This gripper is simple to build and surprisingly strong.

Plastic tool clamps come in a variety of shapes and sizes. You want one that’s as close as

possible to the clamp in Figure 29- 13. The clamp measures 5″ in overall length and is about

Pulley Torsion spring

gear

Tension spring

Torsion spring

Drive

Figure 29- 11 A way to actuate the

gripper. Attach cables to the fingers and pull Figure 29- 12 Actuation detail of a two- pincher gripper

the cables with a servo motor. Fit a torsion using a motor and gears. The tension spring prevents undue

spring (a thin metal strip) along the fingers pressure on the object being grasped. The torsion springs are

and palm to open the fingers when power is thin pieces of brass that act to reopen the gripper fingers when

removed from the motor. the motor shuts off.

29-chapter-29.indd 356 4/21/11 11:53 AM