Page 242 - Robot Builders Source Book - Gordon McComb

P. 242

230 Feeding and Orientation Devices

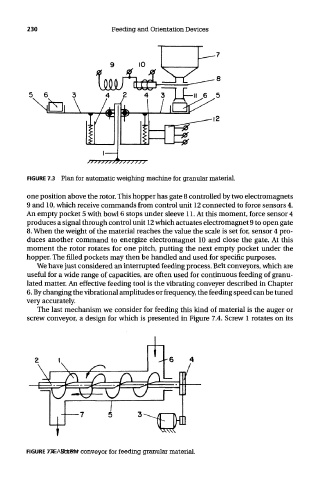

FIGURE 7.3 Plan for automatic weighing machine for granular material.

one position above the rotor. This hopper has gate 8 controlled by two electromagnets

9 and 10, which receive commands from control unit 12 connected to force sensors 4.

An empty pocket 5 with bowl 6 stops under sleeve 11. At this moment, force sensor 4

produces a signal through control unit 12 which actuates electromagnet 9 to open gate

8. When the weight of the material reaches the value the scale is set for, sensor 4 pro-

duces another command to energize electromagnet 10 and close the gate. At this

moment the rotor rotates for one pitch, putting the next empty pocket under the

hopper. The filled pockets may then be handled and used for specific purposes.

We have just considered an interrupted feeding process. Belt conveyors, which are

useful for a wide range of capacities, are often used for continuous feeding of granu-

lated matter. An effective feeding tool is the vibrating conveyer described in Chapter

6. By changing the vibrational amplitudes or frequency, the feeding speed can be tuned

very accurately.

The last mechanism we consider for feeding this kind of material is the auger or

screw conveyor, a design for which is presented in Figure 7.4. Screw 1 rotates on its

TEAM LRN

FIGURE 7.4 Screw conveyor for feeding granular material.