Page 243 - Robots Androids and Animatrons : 12 Incredible Projects You Can Build

P. 243

brought high, the chip operates in the half-step mode. This mode

doubles the resolution of the stepper motor. For instance, the motor

we are using rotates the shaft 1.8 degrees per step. When operating

in the half-step mode, the shaft rotates 0.9 degrees per step and the

overall rotation speed [revolutions per minute (rpm)] of the shaft

will be one-half of the speed of the full-step mode. If pin 10 is

brought to ground, the UCN-5804 will operate in full-step mode.

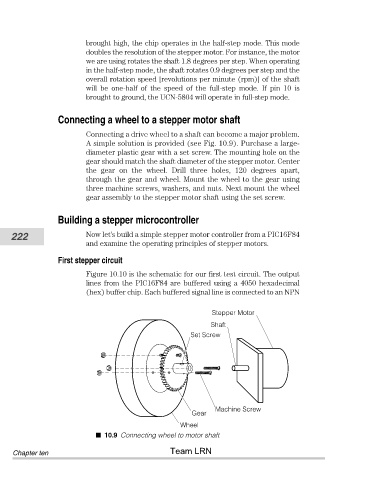

Connecting a wheel to a stepper motor shaft

Connecting a drive wheel to a shaft can become a major problem.

A simple solution is provided (see Fig. 10.9). Purchase a large-

diameter plastic gear with a set screw. The mounting hole on the

gear should match the shaft diameter of the stepper motor. Center

the gear on the wheel. Drill three holes, 120 degrees apart,

through the gear and wheel. Mount the wheel to the gear using

three machine screws, washers, and nuts. Next mount the wheel

gear assembly to the stepper motor shaft using the set screw.

Building a stepper microcontroller

222 Now let’s build a simple stepper motor controller from a PIC16F84

and examine the operating principles of stepper motors.

First stepper circuit

Figure 10.10 is the schematic for our first test circuit. The output

lines from the PIC16F84 are buffered using a 4050 hexadecimal

(hex) buffer chip. Each buffered signal line is connected to an NPN

Stepper Motor

Shaft

Set Screw

Machine Screw

Gear

Wheel

10.9 Connecting wheel to motor shaft

Team LRN

Chapter ten