Page 344 - Rock Mechanics For Underground Mining

P. 344

ROCK SUPPORT AND REINFORCEMENT

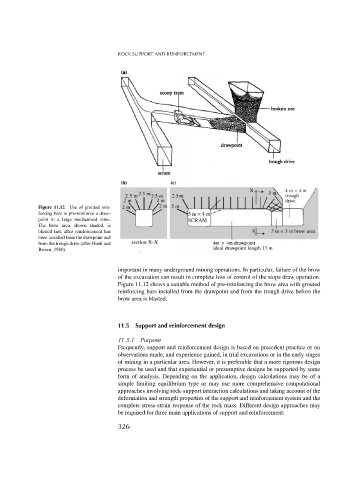

Figure 11.12 Use of grouted rein-

forcing bars to pre-reinforce a draw-

point in a large mechanised mine.

The brow area, shown shaded, is

blasted last, after reinforcement has

been installed from the drawpoint and

from the trough drive (after Hoek and

Brown, 1980).

important in many underground mining operations. In particular, failure of the brow

of the excavation can result in complete loss of control of the stope draw operation.

Figure 11.12 shows a suitable method of pre-reinforcing the brow area with grouted

reinforcing bars installed from the drawpoint and from the trough drive before the

brow area is blasted.

11.5 Support and reinforcement design

11.5.1 Purpose

Frequently, support and reinforcement design is based on precedent practice or on

observations made, and experience gained, in trial excavations or in the early stages

of mining in a particular area. However, it is preferable that a more rigorous design

process be used and that experiential or presumptive designs be supported by some

form of analysis. Depending on the application, design calculations may be of a

simple limiting equilibrium type or may use more comprehensive computational

approaches involving rock-support interaction calculations and taking account of the

deformation and strength properties of the support and reinforcement system and the

complete stress-strain response of the rock mass. Different design approaches may

be required for three main applications of support and reinforcement:

326