Page 574 - Rock Mechanics For Underground Mining

P. 574

MONITORING ROCK MASS PERFORMANCE

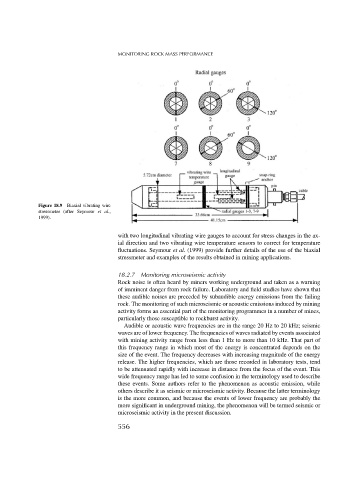

Figure 18.9 Biaxial vibrating wire

stressmeter (after Seymour et al.,

1999).

with two longitudinal vibrating wire gauges to account for stress changes in the ax-

ial direction and two vibrating wire temperature sensors to correct for temperature

fluctuations. Seymour et al. (1999) provide further details of the use of the biaxial

stressmeter and examples of the results obtained in mining applications.

18.2.7 Monitoring microseismic activity

Rock noise is often heard by miners working underground and taken as a warning

of imminent danger from rock failure. Laboratory and field studies have shown that

these audible noises are preceded by subaudible energy emissions from the failing

rock. The monitoring of such microseismic or acoustic emissions induced by mining

activity forms an essential part of the monitoring programmes in a number of mines,

particularly those susceptible to rockburst activity.

Audible or acoustic wave frequencies are in the range 20 Hz to 20 kHz; seismic

waves are of lower frequency. The frequencies of waves radiated by events associated

with mining activity range from less than 1 Hz to more than 10 kHz. That part of

this frequency range in which most of the energy is concentrated depends on the

size of the event. The frequency decreases with increasing magnitude of the energy

release. The higher frequencies, which are those recorded in laboratory tests, tend

to be attenuated rapidly with increase in distance from the focus of the event. This

wide frequency range has led to some confusion in the terminology used to describe

these events. Some authors refer to the phenomenon as acoustic emission, while

others describe it as seismic or microseismic activity. Because the latter terminology

is the more common, and because the events of lower frequency are probably the

more significant in underground mining, the phenomenon will be termed seismic or

microseismic activity in the present discussion.

556