Page 25 - Semiconductor Manufacturing Handbook

P. 25

Geng(SMH)_CH03.qxd 04/04/2005 19:34 Page 3.4

SILICON SUBSTRATES FOR SEMICONDUCTOR MANUFACTURING

3.4 SEMICONDUCTOR FUNDAMENTALS AND BASIC MATERIALS

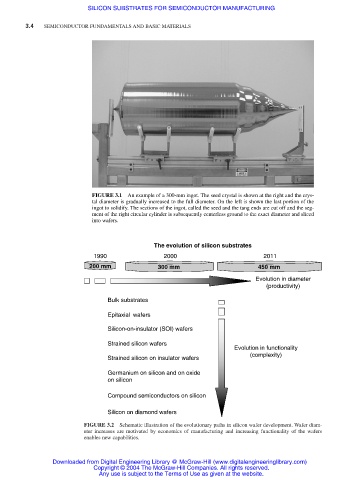

FIGURE 3.1 An example of a 300-mm ingot. The seed crystal is shown at the right and the crys-

tal diameter is gradually increased to the full diameter. On the left is shown the last portion of the

ingot to solidify. The sections of the ingot, called the seed and the tang ends are cut off and the seg-

ment of the right circular cylinder is subsequently centerless ground to the exact diameter and sliced

into wafers.

The evolution of silicon substrates

1990 2000 2011

200 mm 300 mm 450 mm

Evolution in diameter

(productivity)

Bulk substrates

Epitaxial wafers

Silicon-on-insulator (SOI) wafers

Strained silicon wafers

Evolution in functionality

(complexity)

Strained silicon on insulator wafers

Germanium on silicon and on oxide

on silicon

Compound semiconductors on silicon

Silicon on diamond wafers

FIGURE 3.2 Schematic illustration of the evolutionary paths in silicon wafer development. Wafer diam-

eter increases are motivated by economics of manufacturing and increasing functionality of the wafers

enables new capabilities.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.