Page 245 - Sensing, Intelligence, Motion : How Robots and Humans Move in an Unstructured World

P. 245

220 MOTION PLANNING FOR TWO-DIMENSIONAL ARM MANIPULATORS

first, humans’ own motion planning strategies work pretty well in the related

tasks and, second, humans have no problem interpreting, learning, and using

relevant motion planning algorithms. In comparison, motion planning for even

a simple arm manipulator is a task that poses serious mental challenges to a

human. This fact goes a long way in explaining difficulties that human operators

exhibit when controlling real-world teleoperated robotics systems. The price for

those difficulties is operators’ mistakes and an overly slow operation that rules

out many real-life tasks.

This suggests the need for changes in today’s approaches to the design of

teleoperated systems. In particular, it is highly desirable to shift the responsibil-

ity for obstacle collision avoidance from the operator’s shoulders to the robot

intelligence. We will return to this topic in Chapters 7 and 8.

5.3 DISTINCT KINEMATIC CONFIGURATIONS OF RR ARM

Even for the most popular revolute and sliding (prismatic) joint types, each

combination of joint types of an arm manipulator can be realized in more than

one kinematic configuration. The RR arm that we analyzed above (Section 5.2)

is especially prolific in terms of variability of kinematic configurations. We will

review here those configurations, as an example of how such variability occurs

as well as to see how the theory developed above applies to them. This exercise

also helps train one’s spatial intuition, a useful quality in the work we do here.

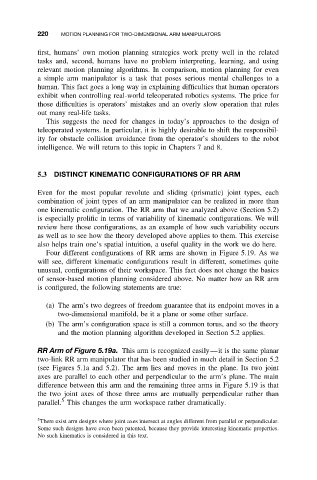

Four different configurations of RR arms are shown in Figure 5.19. As we

will see, different kinematic configurations result in different, sometimes quite

unusual, configurations of their workspace. This fact does not change the basics

of sensor-based motion planning considered above. No matter how an RR arm

is configured, the following statements are true:

(a) The arm’s two degrees of freedom guarantee that its endpoint moves in a

two-dimensional manifold, be it a plane or some other surface.

(b) The arm’s configuration space is still a common torus, and so the theory

and the motion planning algorithm developed in Section 5.2 applies.

RR Arm of Figure 5.19a. This arm is recognized easily—it is the same planar

two-link RR arm manipulator that has been studied in much detail in Section 5.2

(see Figures 5.1a and 5.2). The arm lies and moves in the plane. Its two joint

axes are parallel to each other and perpendicular to the arm’s plane. The main

difference between this arm and the remaining three arms in Figure 5.19 is that

the two joint axes of those three arms are mutually perpendicular rather than

5

parallel. This changes the arm workspace rather dramatically.

5 There exist arm designs where joint axes intersect at angles different from parallel or perpendicular.

Some such designs have even been patented, because they provide interesting kinematic properties.

No such kinematics is considered in this text.