Page 215 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 215

CH15pp159-189 4/10/02 12:51 PM Page 181

Applying the Process Model—A Case Study 181

TABLE 15-6 continued

QMI Warehouse Operations Serious Incident Prevention Critical Work

Critical Work Frequency

g) Lock-out procedures for controlling

hazardous energy

h) Lift-truck training

i) Hazard communication

Facility orientation and site visit for local Annual

emergency response agencies

Emergency Drill Annual

Alarm tests:

a) Smoke detectors Monthly for all items

b) Fire alarm system

c) Security system

Process hazards analysis by cross-func- Every 3 years

tional team

Investigation of incidents and near-miss Within 24 hours of occurrence

incidents with serious potential

Comprehensive review and update of se- Annual

rious incident prevention process

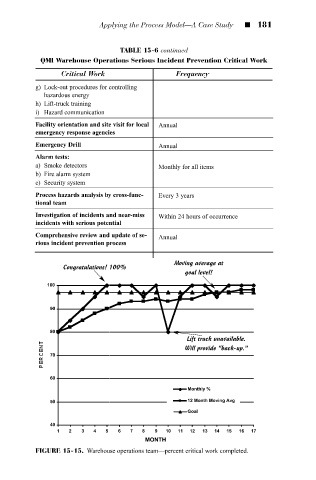

Moving average at

Congratulations! 100%

goal level!

100

90

80

Lift truck unavailable.

Will provide “back-up.”

70

60

Monthly %

50 12 Month Moving Avg

Goal

40

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

MONTH

FIGURE 15-15. Warehouse operations team—percent critical work completed.