Page 220 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 220

CH15pp159-189 4/10/02 12:51 PM Page 186

186 Serious Incident Prevention

5

Survey Results 4

3

2

1

1 2 3 4 5 6

Year

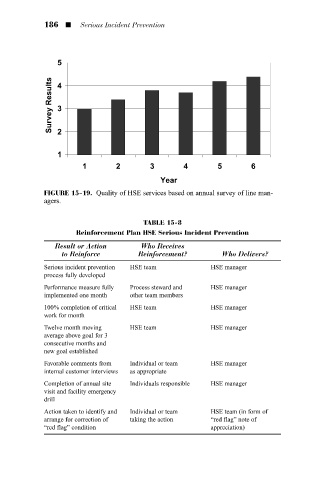

FIGURE 15-19. Quality of HSE services based on annual survey of line man-

agers.

TABLE 15-8

Reinforcement Plan HSE Serious Incident Prevention

Result or Action Who Receives

to Reinforce Reinforcement? Who Delivers?

Serious incident prevention HSE team HSE manager

process fully developed

Performance measure fully Process steward and HSE manager

implemented one month other team members

100% completion of critical HSE team HSE manager

work for month

Twelve month moving HSE team HSE manager

average above goal for 3

consecutive months and

new goal established

Favorable comments from Individual or team HSE manager

internal customer interviews as appropriate

Completion of annual site Individuals responsible HSE manager

visit and facility emergency

drill

Action taken to identify and Individual or team HSE team (in form of

arrange for correction of taking the action “red flag” note of

“red flag” condition appreciation)