Page 217 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 217

CH15pp159-189 4/10/02 12:51 PM Page 183

Applying the Process Model—A Case Study 183

HSE—Serious Incident

Prevention Processes

The actions of QMI’s Health, Safety, and Environmental department sig-

nificantly impact the company’s capability to sustain serious incident-free

operations. The HSE department utilizes all elements of the serious incident

prevention process to ensure services supporting incident-free operations are

effectively provided. The team’s critical work is targeted towards minimizing

both the probability and potential consequences of an incident.

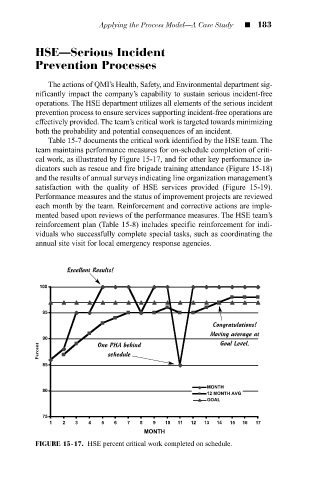

Table 15-7 documents the critical work identified by the HSE team. The

team maintains performance measures for on-schedule completion of criti-

cal work, as illustrated by Figure 15-17, and for other key performance in-

dicators such as rescue and fire brigade training attendance (Figure 15-18)

and the results of annual surveys indicating line organization management’s

satisfaction with the quality of HSE services provided (Figure 15-19).

Performance measures and the status of improvement projects are reviewed

each month by the team. Reinforcement and corrective actions are imple-

mented based upon reviews of the performance measures. The HSE team’s

reinforcement plan (Table 15-8) includes specific reinforcement for indi-

viduals who successfully complete special tasks, such as coordinating the

annual site visit for local emergency response agencies.

Excellent Results!

100

95

Congratulations!

Moving average at

90 Goal Level.

Percent One PHA behind

schedule

85

MONTH

80

12 MONTH AVG

GOAL

75

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

MONTH

FIGURE 15-17. HSE percent critical work completed on schedule.