Page 221 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 221

CH15pp159-189 4/10/02 12:51 PM Page 187

Applying the Process Model—A Case Study 187

HSE personnel maintain active dialogue with the manufacturing and

chemical handling areas. This interaction helps team members clearly un-

derstand the risks that must be controlled and the specific HSE support re-

quired. The team’s expertise is recognized, and members are often invited to

participate in improvement efforts initiated by the manufacturing and chem-

ical handling departments. The HSE team is highly respected throughout

the company, and the team is proud of its contributions and partnership role

with line organizations.

QMI Site Management Team:

Serious Incident Prevention

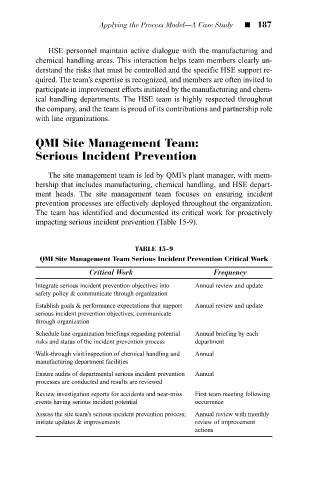

The site management team is led by QMI’s plant manager, with mem-

bership that includes manufacturing, chemical handling, and HSE depart-

ment heads. The site management team focuses on ensuring incident

prevention processes are effectively deployed throughout the organization.

The team has identified and documented its critical work for proactively

impacting serious incident prevention (Table 15-9).

TABLE 15-9

QMI Site Management Team Serious Incident Prevention Critical Work

Critical Work Frequency

Integrate serious incident prevention objectives into Annual review and update

safety policy & communicate through organization

Establish goals & performance expectations that support Annual review and update

serious incident prevention objectives; communicate

through organization

Schedule line organization briefings regarding potential Annual briefing by each

risks and status of the incident prevention process department

Walk-through visit/inspection of chemical handling and Annual

manufacturing department facilities

Ensure audits of departmental serious incident prevention Annual

processes are conducted and results are reviewed

Review investigation reports for accidents and near-miss First team meeting following

events having serious incident potential occurrence

Assess the site team’s serious incident prevention process; Annual review with monthly

initiate updates & improvements review of improvement

actions