Page 406 - Shigley's Mechanical Engineering Design

P. 406

bud29281_ch07_358-408.qxd 12/9/09 4:29PM Page 381 ntt 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

Shafts and Shaft Components 381

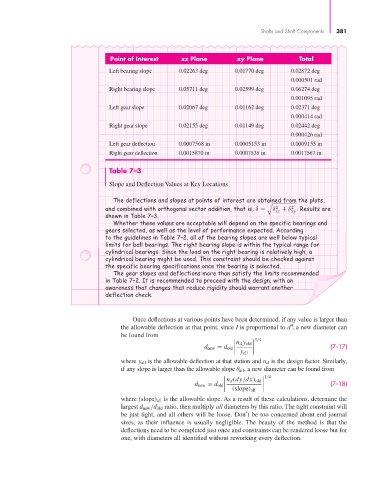

Point of Interest xz Plane xy Plane Total

Left bearing slope 0.02263 deg 0.01770 deg 0.02872 deg

0.000501 rad

Right bearing slope 0.05711 deg 0.02599 deg 0.06274 deg

0.001095 rad

Left gear slope 0.02067 deg 0.01162 deg 0.02371 deg

0.000414 rad

Right gear slope 0.02155 deg 0.01149 deg 0.02442 deg

0.000426 rad

Left gear deflection 0.0007568 in 0.0005153 in 0.0009155 in

Right gear deflection 0.0015870 in 0.0007535 in 0.0017567 in

Table 7–3

Slope and Deflection Values at Key Locations

The deflections and slopes at points of interest are obtained from the plots,

2

2

and combined with orthogonal vector addition, that is, δ = δ + δ . Results are

xz xy

shown in Table 7–3.

Whether these values are acceptable will depend on the specific bearings and

gears selected, as well as the level of performance expected. According

to the guidelines in Table 7–2, all of the bearing slopes are well below typical

limits for ball bearings. The right bearing slope is within the typical range for

cylindrical bearings. Since the load on the right bearing is relatively high, a

cylindrical bearing might be used. This constraint should be checked against

the specific bearing specifications once the bearing is selected.

The gear slopes and deflections more than satisfy the limits recommended

in Table 7–2. It is recommended to proceed with the design, with an

awareness that changes that reduce rigidity should warrant another

deflection check.

Once deflections at various points have been determined, if any value is larger than

4

the allowable deflection at that point, since I is proportional to d , a new diameter can

be found from

1/4

n d y old

(7–17)

y all

d new = d old

where y all is the allowable deflection at that station and n d is the design factor. Similarly,

if any slope is larger than the allowable slope θ all , a new diameter can be found from

1/4

n d (dy/dx) old

(7–18)

(slope) all

d new = d old

where (slope) all is the allowable slope. As a result of these calculations, determine the

largest d new /d old ratio, then multiply all diameters by this ratio. The tight constraint will

be just tight, and all others will be loose. Don’t be too concerned about end journal

sizes, as their influence is usually negligible. The beauty of the method is that the

deflections need to be completed just once and constraints can be rendered loose but for

one, with diameters all identified without reworking every deflection.