Page 450 - Shigley's Mechanical Engineering Design

P. 450

bud29281_ch08_409-474.qxd 12/19/2009 11:34 am Page 425 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

Screws, Fasteners, and the Design of Nonpermanent Joints 425

Figure 8–13 P P

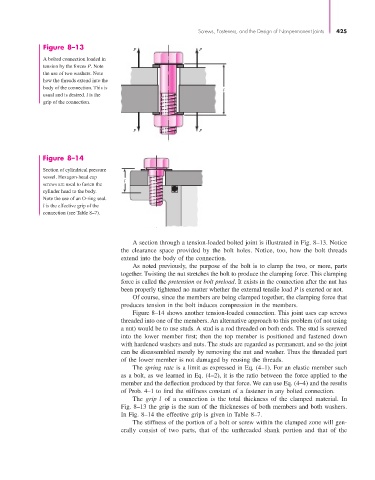

A bolted connection loaded in

tension by the forces P. Note

the use of two washers. Note

how the threads extend into the

body of the connection. This is l

usual and is desired. l is the

grip of the connection.

P P

Figure 8–14

Section of cylindrical pressure

vessel. Hexagon-head cap

l

screws are used to fasten the

cylinder head to the body.

Note the use of an O-ring seal.

l is the effective grip of the

connection (see Table 8–7).

A section through a tension-loaded bolted joint is illustrated in Fig. 8–13. Notice

the clearance space provided by the bolt holes. Notice, too, how the bolt threads

extend into the body of the connection.

As noted previously, the purpose of the bolt is to clamp the two, or more, parts

together. Twisting the nut stretches the bolt to produce the clamping force. This clamping

force is called the pretension or bolt preload. It exists in the connection after the nut has

been properly tightened no matter whether the external tensile load P is exerted or not.

Of course, since the members are being clamped together, the clamping force that

produces tension in the bolt induces compression in the members.

Figure 8–14 shows another tension-loaded connection. This joint uses cap screws

threaded into one of the members. An alternative approach to this problem (of not using

a nut) would be to use studs. A stud is a rod threaded on both ends. The stud is screwed

into the lower member first; then the top member is positioned and fastened down

with hardened washers and nuts. The studs are regarded as permanent, and so the joint

can be disassembled merely by removing the nut and washer. Thus the threaded part

of the lower member is not damaged by reusing the threads.

The spring rate is a limit as expressed in Eq. (4–1). For an elastic member such

as a bolt, as we learned in Eq. (4–2), it is the ratio between the force applied to the

member and the deflection produced by that force. We can use Eq. (4–4) and the results

of Prob. 4–1 to find the stiffness constant of a fastener in any bolted connection.

The grip l of a connection is the total thickness of the clamped material. In

Fig. 8–13 the grip is the sum of the thicknesses of both members and both washers.

In Fig. 8–14 the effective grip is given in Table 8–7.

The stiffness of the portion of a bolt or screw within the clamped zone will gen-

erally consist of two parts, that of the unthreaded shank portion and that of the