Page 451 - Shigley's Mechanical Engineering Design

P. 451

bud29281_ch08_409-474.qxd 12/16/2009 7:11 pm Page 426 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

426 Mechanical Engineering Design

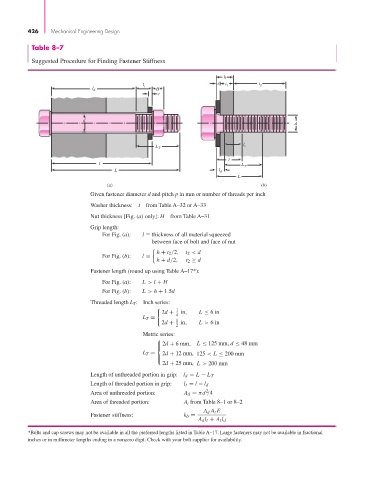

Table 8–7

Suggested Procedure for Finding Fastener Stiffness

h

t t t

l t 1 2

l d H

t

d

d

l

L T t

l

l L

T

L l d

L

(a) (b)

Given fastener diameter d and pitch p in mm or number of threads per inch

Washer thickness: t from Table A–32 or A–33

Nut thickness [Fig. (a) only]: H from Table A–31

Grip length:

For Fig. (a): l thickness of all material squeezed

between face of bolt and face of nut

h + t 2 /2, t 2 < d

For Fig. (b): l =

h + d/2, t 2 ≥ d

Fastener length (round up using Table A–17*):

For Fig. (a): L > l + H

For Fig. (b): L > h + 1.5d

Threaded length L T: Inch series:

1

2d + 4 in, L ≤ 6in

L T = 1

2d + in, L > 6in

2

Metric series:

⎧

⎪ 2d + 6mm, L ≤ 125 mm, d ≤ 48 mm

⎨

L T = 2d + 12 mm, 125 < L ≤ 200 mm

⎪

⎩

2d + 25 mm, L > 200 mm

Length of unthreaded portion in grip: l d = L − L T

Length of threaded portion in grip: l t = l − l d

2

Area of unthreaded portion: A d = πd /4

Area of threaded portion: A t from Table 8–1 or 8–2

A d A t E

Fastener stiffness: k b =

A d l t + A t l d

*Bolts and cap screws may not be available in all the preferred lengths listed in Table A–17. Large fasteners may not be available in fractional

inches or in millimeter lengths ending in a nonzero digit. Check with your bolt supplier for availability.