Page 485 - Shigley's Mechanical Engineering Design

P. 485

bud29281_ch08_409-474.qxd 12/16/2009 7:11 pm Page 460 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

460 Mechanical Engineering Design

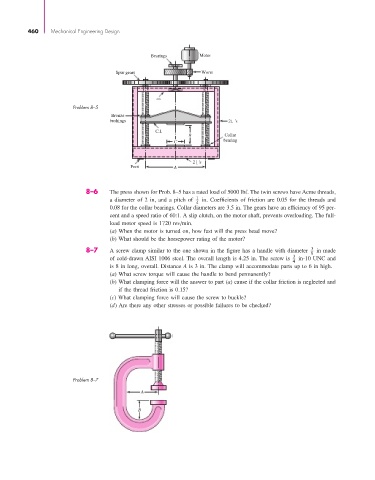

Bearings Motor

Spur gears Worm

Problem 8–5 [

Bronze

bushings 2 's

C.I.

B Collar

C bearing

2 [ 's

Foot A

8–6 The press shown for Prob. 8–5 has a rated load of 5000 lbf. The twin screws have Acme threads,

a diameter of 2 in, and a pitch of 1 4 in. Coefficients of friction are 0.05 for the threads and

0.08 for the collar bearings. Collar diameters are 3.5 in. The gears have an efficiency of 95 per-

cent and a speed ratio of 60:1. A slip clutch, on the motor shaft, prevents overloading. The full-

load motor speed is 1720 rev/min.

(a) When the motor is turned on, how fast will the press head move?

(b) What should be the horsepower rating of the motor?

8–7 A screw clamp similar to the one shown in the figure has a handle with diameter 3 8 in made

of cold-drawn AISI 1006 steel. The overall length is 4.25 in. The screw is 3 4 in-10 UNC and

is 8 in long, overall. Distance A is 3 in. The clamp will accommodate parts up to 6 in high.

(a) What screw torque will cause the handle to bend permanently?

(b) What clamping force will the answer to part (a) cause if the collar friction is neglected and

if the thread friction is 0.15?

(c) What clamping force will cause the screw to buckle?

(d) Are there any other stresses or possible failures to be checked?

Problem 8–7

A

B