Page 159 - Six Sigma for electronics design and manufacturing

P. 159

Six Sigma for Electronics Design and Manufacturing

128

bad test effectiveness, and good test effectiveness. They are measured

as percentage values:

1. Test coverage (%): the test coverage for a given fault. Coverage of 0

for a defect category means that this defect is not tested.

2. Bad test effectiveness (%): the percentage of bad components that

fail a test. Thus, a tester with 100% bad test effectiveness will fail

all bad items, whereas one with 0% bad test effectiveness will pass

all bad items.

3. Good test effectiveness (%): the percentage of good parts that pass

a test. Thus, a tester with 100% good test effectiveness will pass all

good items, whereas one with 0% good test effectiveness will fail all

good items.

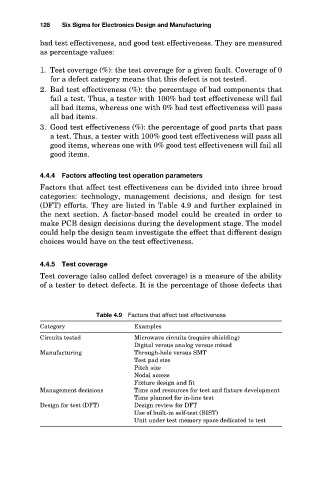

4.4.4 Factors affecting test operation parameters

Factors that affect test effectiveness can be divided into three broad

categories: technology, management decisions, and design for test

(DFT) efforts. They are listed in Table 4.9 and further explained in

the next section. A factor-based model could be created in order to

make PCB design decisions during the development stage. The model

could help the design team investigate the effect that different design

choices would have on the test effectiveness.

4.4.5 Test coverage

Test coverage (also called defect coverage) is a measure of the ability

of a tester to detect defects. It is the percentage of those defects that

Table 4.9 Factors that affect test effectiveness

Category Examples

Circuits tested Microwave circuits (require shielding)

Digital versus analog versus mixed

Manufacturing Through-hole versus SMT

Test pad size

Pitch size

Nodal access

Fixture design and fit

Management decisions Time and resources for test and fixture development

Time planned for in-line test

Design for test (DFT) Design review for DFT

Use of built-in self-test (BIST)

Unit under test memory space dedicated to test