Page 157 - Six Sigma for electronics design and manufacturing

P. 157

Six Sigma for Electronics Design and Manufacturing

126

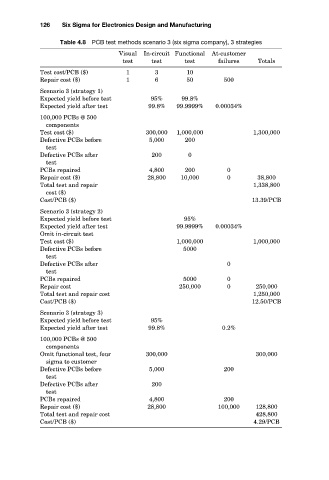

Table 4.8 PCB test methods scenario 3 (six sigma company), 3 strategies

failures

test

test

test

10

1

Test cost/PCB ($)

3

1

6

Repair cost ($)

50

500

Scenario 3 (strategy 1)

Expected yield before test

99.8%

95%

99.8%

99.9999%

Expected yield after test

0.00034%

100,000 PCBs @ 500

components Visual In-circuit Functional At-customer Totals

Test cost ($) 300,000 1,000,000 1,300,000

Defective PCBs before 5,000 200

test

Defective PCBs after 200 0

test

PCBs repaired 4,800 200 0

Repair cost ($) 28,800 10,000 0 38,800

Total test and repair 1,338,800

cost ($)

Cost/PCB ($) 13.39/PCB

Scenario 3 (strategy 2)

Expected yield before test 95%

Expected yield after test 99.9999% 0.00034%

Omit in-circuit test

Test cost ($) 1,000,000 1,000,000

Defective PCBs before 5000

test

Defective PCBs after 0

test

PCBs repaired 5000 0

Repair cost 250,000 0 250,000

Total test and repair cost 1,250,000

Cost/PCB ($) 12.50/PCB

Scenario 3 (strategy 3)

Expected yield before test 95%

Expected yield after test 99.8% 0.2%

100,000 PCBs @ 500

components

Omit functional test, four 300,000 300,000

sigma to customer

Defective PCBs before 5,000 200

test

Defective PCBs after 200

test

PCBs repaired 4,800 200

Repair cost ($) 28,800 100,000 128,800

Total test and repair cost 428,800

Cost/PCB ($) 4.29/PCB