Page 155 - Six Sigma for electronics design and manufacturing

P. 155

124

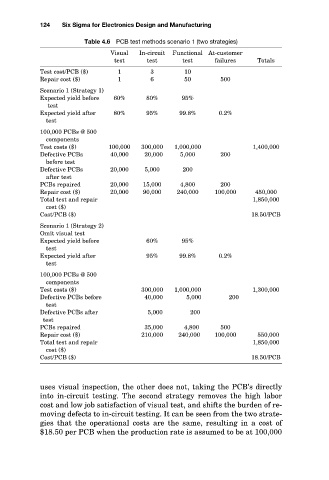

Table 4.6 PCB test methods scenario 1 (two strategies)

Visual

Functional At-customer

In-circuit

test

test

test

1

3

10

Test cost/PCB ($)

50

500

1

Repair cost ($)

6

Scenario 1 (Strategy 1)

95%

80%

Expected yield before

60%

test

95%

99.8%

Expected yield after

80%

0.2%

test Six Sigma for Electronics Design and Manufacturing failures Totals

100,000 PCBs @ 500

components

Test costs ($) 100,000 300,000 1,000,000 1,400,000

Defective PCBs 40,000 20,000 5,000 200

before test

Defective PCBs 20,000 5,000 200

after test

PCBs repaired 20,000 15,000 4,800 200

Repair cost ($) 20,000 90,000 240,000 100,000 450,000

Total test and repair 1,850,000

cost ($)

Cost/PCB ($) 18.50/PCB

Scenario 1 (Strategy 2)

Omit visual test

Expected yield before 60% 95%

test

Expected yield after 95% 99.8% 0.2%

test

100,000 PCBs @ 500

components

Test costs ($) 300,000 1,000,000 1,300,000

Defective PCBs before 40,000 5,000 200

test

Defective PCBs after 5,000 200

test

PCBs repaired 35,000 4,800 500

Repair cost ($) 210,000 240,000 100,000 550,000

Total test and repair 1,850,000

cost ($)

Cost/PCB ($) 18.50/PCB

uses visual inspection, the other does not, taking the PCB’s directly

into in-circuit testing. The second strategy removes the high labor

cost and low job satisfaction of visual test, and shifts the burden of re-

moving defects to in-circuit testing. It can be seen from the two strate-

gies that the operational costs are the same, resulting in a cost of

$18.50 per PCB when the production rate is assumed to be at 100,000