Page 186 - Six Sigma for electronics design and manufacturing

P. 186

The Use of Six Sigma with High- and Low-Volume Products and Processes

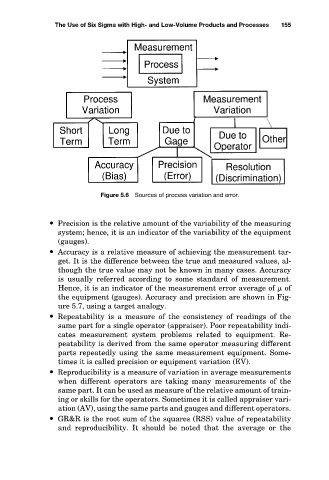

Figure 5.6 Sources of process variation and error. 155

Precision is the relative amount of the variability of the measuring

system; hence, it is an indicator of the variability of the equipment

(gauges).

Accuracy is a relative measure of achieving the measurement tar-

get. It is the difference between the true and measured values, al-

though the true value may not be known in many cases. Accuracy

is usually referred according to some standard of measurement.

Hence, it is an indicator of the measurement error average of of

the equipment (gauges). Accuracy and precision are shown in Fig-

ure 5.7, using a target analogy.

Repeatability is a measure of the consistency of readings of the

same part for a single operator (appraiser). Poor repeatability indi-

cates measurement system problems related to equipment. Re-

peatability is derived from the same operator measuring different

parts repeatedly using the same measurement equipment. Some-

times it is called precision or equipment variation (EV).

Reproducibility is a measure of variation in average measurements

when different operators are taking many measurements of the

same part. It can be used as measure of the relative amount of train-

ing or skills for the operators. Sometimes it is called appraiser vari-

ation (AV), using the same parts and gauges and different operators.

GR&R is the root sum of the squares (RSS) value of repeatability

and reproducibility. It should be noted that the average or the