Page 190 - Steam Turbines Design, Applications, and Rerating

P. 190

Rotor Dynamics Technology 169

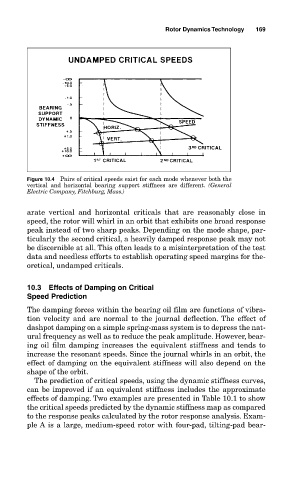

Figure 10.4 Pairs of critical speeds exist for each mode whenever both the

vertical and horizontal bearing support stiffness are different. (General

Electric Company, Fitchburg, Mass.)

arate vertical and horizontal criticals that are reasonably close in

speed, the rotor will whirl in an orbit that exhibits one broad response

peak instead of two sharp peaks. Depending on the mode shape, par-

ticularly the second critical, a heavily damped response peak may not

be discernible at all. This often leads to a misinterpretation of the test

data and needless efforts to establish operating speed margins for the-

oretical, undamped criticals.

10.3 Effects of Damping on Critical

Speed Prediction

The damping forces within the bearing oil film are functions of vibra-

tion velocity and are normal to the journal deflection. The effect of

dashpot damping on a simple spring-mass system is to depress the nat-

ural frequency as well as to reduce the peak amplitude. However, bear-

ing oil film damping increases the equivalent stiffness and tends to

increase the resonant speeds. Since the journal whirls in an orbit, the

effect of damping on the equivalent stiffness will also depend on the

shape of the orbit.

The prediction of critical speeds, using the dynamic stiffness curves,

can be improved if an equivalent stiffness includes the approximate

effects of damping. Two examples are presented in Table 10.1 to show

the critical speeds predicted by the dynamic stiffness map as compared

to the response peaks calculated by the rotor response analysis. Exam-

ple A is a large, medium-speed rotor with four-pad, tilting-pad bear-