Page 158 - Sustainability in the Process Industry Integration and Optimization

P. 158

Fu r t h e r A p p l i c a t i o n s o f P r o c e s s I n t e g r a t i o n 135

Unused Materials or

Discharged Waste

U + U + U 3

1

2

Source 2

U 1 + U 2

Load [kg/s] U 1

Source 1

Flowrate [kg/s]

Minimum

Fresh Usage

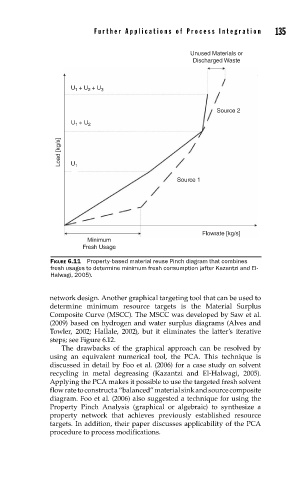

FIGURE 6.11 Property-based material reuse Pinch diagram that combines

fresh usages to determine minimum fresh consumption (after Kazantzi and El-

Halwagi, 2005).

network design. Another graphical targeting tool that can be used to

determine minimum resource targets is the Material Surplus

Composite Curve (MSCC). The MSCC was developed by Saw et al.

(2009) based on hydrogen and water surplus diagrams (Alves and

Towler, 2002; Hallale, 2002), but it eliminates the latter’s iterative

steps; see Figure 6.12.

The drawbacks of the graphical approach can be resolved by

using an equivalent numerical tool, the PCA. This technique is

discussed in detail by Foo et al. (2006) for a case study on solvent

recycling in metal degreasing (Kazantzi and El-Halwagi, 2005).

Applying the PCA makes it possible to use the targeted fresh solvent

flow rate to construct a “balanced” material sink and source composite

diagram. Foo et al. (2006) also suggested a technique for using the

Property Pinch Analysis (graphical or algebraic) to synthesize a

property network that achieves previously established resource

targets. In addition, their paper discusses applicability of the PCA

procedure to process modifications.