Page 196 - Sustainability in the Process Industry Integration and Optimization

P. 196

Co m b i n e d P r o c e s s I n t e g r a t i o n a n d O p t i m i z a t i o n 173

Double Pressing

5289 t/y Water added

for second pressing

Silage Presscake

Feed Matter 35511 t/y Feed Matter 13825 t/y

Dry Matter 10000 t/y Dry Matter 6636 t/y

Dry Matter 28.16 % Dry Matter 48 %

Lactic Acid 1000 t/y Lactic Acid 215 t/y

Raw Fibre 2825.7 t/y Raw Fibre 2824 t/y

Org. Dry Matter 8992 t/y Org. Dry Matter 6483 t/y

Flux-out 1.9 t FM/h

Silage Juice

Feed Matter 26976 t/y

Dry Matter 3364 t/y

Dry Matter 13 %

Lactic Acid 785 t/y

Org. Dry Matter 2509 t/y

Flux-out 3.6 t FM/h

Heat: Drying: Heat to increase Energy for Drying:

183442 603924 concentration: 6451609 kWh/y

kWh/y kWh/y 167033 kWh/y

Lactic Acid 80% D/L

Amino Acids

Conc. 80 %

Feed Matter 755 t/y Feed Matter Product 884 t/y Fibres

Dry Matter 679 t/y Dry Matter 707 t/y Feed Matter 7373 t/y

Dry Matter 90 % Dry Matter 6636 t/y

Org. Dry Matter 706 t/y

Lactic Acid 3.08 t/y Pure Lactic Acid 706 t/y Dry Matter 90 %

Crude Prot. 666 t/y Lactic Acid 215 t/y

Flux-out 0.12 t/h

Flux-out 0.1 t FM/h Raw Fibre 2824 t/y

Crude Protein 98 % DM Org. Dry Matter 6483 t/y

Flux-out 1 t/h

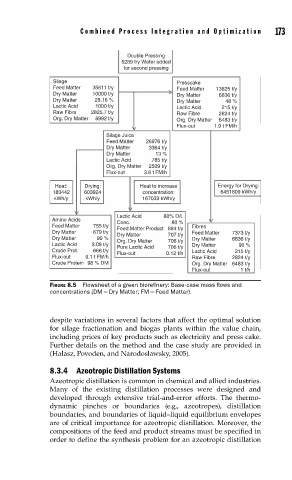

FIGURE 8.5 Flowsheet of a green biorefi nery: Base-case mass fl ows and

concentrations (DM = Dry Matter; FM = Feed Matter).

despite variations in several factors that affect the optimal solution

for silage fractionation and biogas plants within the value chain,

including prices of key products such as electricity and press cake.

Further details on the method and the case study are provided in

(Halasz, Povoden, and Narodoslawsky, 2005).

8.3.4 Azeotropic Distillation Systems

Azeotropic distillation is common in chemical and allied industries.

Many of the existing distillation processes were designed and

developed through extensive trial-and-error efforts. The thermo-

dynamic pinches or boundaries (e.g., azeotropes), distillation

boundaries, and boundaries of liquid–liquid equilibrium envelopes

are of critical importance for azeotropic distillation. Moreover, the

compositions of the feed and product streams must be specified in

order to define the synthesis problem for an azeotropic distillation