Page 208 - Sustainability in the Process Industry Integration and Optimization

P. 208

Co m b i n e d P r o c e s s I n t e g r a t i o n a n d O p t i m i z a t i o n 185

number of options. This optimization task may have several different objectives.

The most obvious are maximizing the system profit (minimizing its cost) and

minimizing the amount of CO emissions. Although it is mathematically

2

possible to define a multiobjective criterion to be optimized, using profitability

alone seems most coherent with the logic of a market economy because profit

drives the behavior of companies. Therefore, in this discussion the system profit

is used as the objective (to be maximized); CO emissions are then used as an

2

additional criterion during the analysis stage.

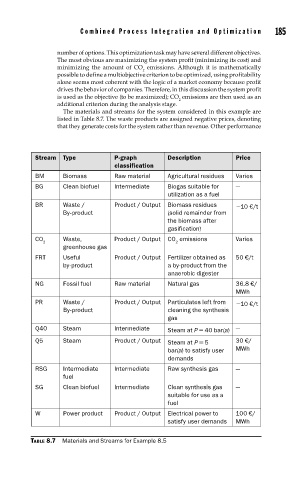

The materials and streams for the system considered in this example are

listed in Table 8.7. The waste products are assigned negative prices, denoting

that they generate costs for the system rather than revenue. Other performance

Stream Type P-graph Description Price

classification

BM Biomass Raw material Agricultural residues Varies

BG Clean biofuel Intermediate Biogas suitable for —

utilization as a fuel

BR Waste / Product / Output Biomass residues −10 €/t

By-product (solid remainder from

the biomass after

gasification)

CO Waste, Product / Output CO emissions Varies

2 2

greenhouse gas

FRT Useful Product / Output Fertilizer obtained as 50 €/t

by-product a by-product from the

anaerobic digester

NG Fossil fuel Raw material Natural gas 36.8 €/

MWh

PR Waste / Product / Output Particulates left from −10 €/t

By-product cleaning the synthesis

gas

Q40 Steam Intermediate Steam at P = 40 bar(a) —

Q5 Steam Product / Output Steam at P = 5 30 €/

bar(a) to satisfy user MWh

demands

RSG Intermediate Intermediate Raw synthesis gas —

fuel

SG Clean biofuel Intermediate Clean synthesis gas —

suitable for use as a

fuel

W Power product Product / Output Electrical power to 100 €/

satisfy user demands MWh

TABLE 8.7 Materials and Streams for Example 8.5