Page 260 - Sustainability in the Process Industry Integration and Optimization

P. 260

E x a m p l e s a n d Ca s e S t u d i e s 237

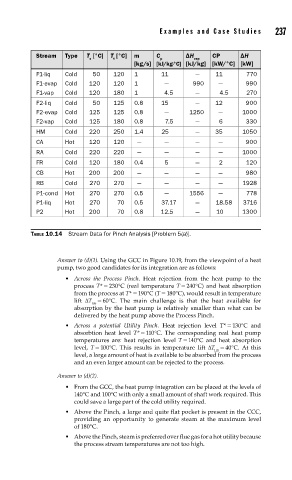

Stream Type T [°C] T [°C] m C ΔH CP ΔH

s t p vap

[kg/s] [kJ/kg·°C] [kJ/kg] [kW/°C] [kW]

F1-liq Cold 50 120 1 11 — 11 770

F1-evap Сold 120 120 1 — 990 — 990

F1-vap Сold 120 180 1 4.5 — 4.5 270

F2-liq Cold 50 125 0.8 15 — 12 900

F2-evap Cold 125 125 0.8 — 1250 — 1000

F2-vap Cold 125 180 0.8 7.5 — 6 330

HM Cold 220 250 1.4 25 — 35 1050

CA Hot 120 120 — — — — 900

RA Cold 220 220 — — — — 1000

FR Cold 120 180 0.4 5 — 2 120

CB Hot 200 200 — — — — 980

RB Cold 270 270 — — — — 1928

P1-cond Hot 270 270 0.5 — 1556 — 778

P1-liq Hot 270 70 0.5 37.17 — 18.58 3716

P2 Hot 200 70 0.8 12.5 — 10 1300

TABLE 10.14 Stream Data for Pinch Analysis [Problem 5(a)].

Answer to (d)(1). Using the GCC in Figure 10.19, from the viewpoint of a heat

pump, two good candidates for its integration are as follows:

• Across the Process Pinch. Heat rejection from the heat pump to the

process T* = 230°C (real temperature T = 240°C) and heat absorption

from the process at T* = 190°C (T = 180°C), would result in temperature

lift ΔT = 60°C. The main challenge is that the heat available for

lift

absorption by the heat pump is relatively smaller than what can be

delivered by the heat pump above the Process Pinch.

• Across a potential Utility Pinch. Heat rejection level T* = 130°C and

absorbtion heat level T* = 110°C. The corresponding real heat pump

temperatures are: heat rejection level T = 140°C and heat absorption

level, T = 100°C. This results in temperature lift ΔT = 40°C. At this

lift

level, a large amount of heat is available to be absorbed from the process

and an even larger amount can be rejected to the process.

Answer to (d)(2).

• From the GCC, the heat pump integration can be placed at the levels of

140°C and 100°C with only a small amount of shaft work required. This

could save a large part of the cold utility required.

• Above the Pinch, a large and quite flat pocket is present in the CCC,

providing an opportunity to generate steam at the maximum level

of 180°C.

• Above the Pinch, steam is preferred over flue gas for a hot utility because

the process stream temperatures are not too high.